Rusch Bandsaws Brand Guide

Rusch is one of the most popular brands in bandsaw manufacture. Highly specialised Rusch cutting machines feature the latest innovative technology and offer a high degree of accuracy, while being easy to operate over a wide range of applications. Rusch bandsaws are highly durable and well-known for effortlessly cutting materials such as steel and plastic with clean, crisp edges. Today, the Rusch range of bandsaws are precision engineered in Thiene, northern Italy, but part of the company's origins lie in Austria

The History of Rusch Bandsaws

In 1827, a small iron foundry producing agricultural hand tools was established in Dornbirn, a small Alpine village in the far west of Austria near the borders of Liechtenstein, Switzerland and Germany. Thirty years later, the foundry had been purchased by Karl Alfred Rusch (1831-1892). He began making machinery for local factories in the textile industry.

First Bandsaw for Metal

By the end of the nineteenth century, Karl's son, Josef Ignaz Rusch, was in charge of the family business. He was eager to expand the company's product range and convinced his three brothers, Walter, Karl and Alfred, that there was a great potential for their future prosperity in the manufacture of bandsaws.

Rusch first supplied bandsaws to workshops involved in the local timber trade. However, one of the company's earliest innovations was the development of the first bandsaw made specifically to cut metal. It would transform manufacturing and secure Rusch a formidable reputation.

Original Rusch Bandsaws

When Josef Ignaz Rusch was first manufacturing bandsaws in the nineteenth century, the machines were quite different from the sophisticated models we have today. They often had an open frame with large wheels to hold the blade and were generally noisy and suffered from high levels of vibration.

Compact versions destined for use in small workshops would have been powered by the operator using a foot pedal, while large industrial bandsaws consisted of a complex network of overhead shafts, pulleys and wheels. They were usually driven by steam, but depending on their geographic location, the bandsaws could also be powered by water mills or windmills.

Hacksaw Blades

Meanwhile, in 1907, Silvio Scortegagna of Vicenza, north Italy, had purchased a small workshop. He began manufacturing a range of machines and accessories for spinning and weaving wool. By 1946, Scortegagna's descendants had adapted the business and were now producing high-quality, industrial hacksaw machines.

Well-known, innovative lines included Ercole manual blades and the automated Ercolematic. In 1970, Scortegagna made what was then the world's largest hacksaw blade, the Ercole 1000HE. In spite of the company's success, the hacksaw industry was about to go into a steady decline. Scortegagna needed to diversify to survive.

Scortegagna/Rusch Company Merger

In 1982, Scortegagna acquired Rusch and wisely retained the brand name. The new company's future production was to concentrate on manufacturing powerful bandsaws, and Rusch brought along a ready-made reputation as a pioneer in the industry.

As Scortegagna expected, the new Rusch was quickly established. The company was further strengthened by its development of reliably versatile, innovative bandsaws. Over the next twenty years the company continued to develop its product range and introduced a range of innovative models including efficient mitre cutting bandsaw machines. Some of these had been designed with cutting capabilities of more than 1,000 millimetres.

Today, Rusch is based in Thiene, a small industrial town located between Venice and Milan. It operates from a large, purpose-built factory covering over 15,000 square metres, and is a leading manufacturer of cutting machines to serve the global market.

Rusch Bandsaws at Saws UK

In recent years, the success of Rusch has been fuelled by technological innovation. The company has created a substantial core of highly sophisticated bandsaws and continues to add to its impressive catalogue of advanced cutting machines.

At Saws UK, we offer an extensive range of Rusch bandsaws that combine high performance with strength, reliability and efficiency. They can easily cut through all types of materials including stainless steel, aluminium and plastic. Rusch cutting machines are available in three categories: manual, semi-automatic and fully automatic.

Rusch Manual Bandsaws

Manual bandsaws generally have a lever that the operator pulls down to align the bow correctly when cutting is about to begin. When finished, the lever must be returned manually to its original position. Rusch manual bandsaws are an ideal choice for small workshops or low volume applications.

Typical Features of Rusch Manual Bandsaws

Although manual Rusch bandsaws have a fairly compact design, they provide versatile solutions for many cutting applications. They usually offer an average capacity for cutting metal tubes and other three-dimensional profiles of approximately 170 mm up to around 250 mm.

Every model in the manual category is generally available in a single or three-phase format. A sturdy, stable base conceals a cooling tank equipped with an electric pump and pipes that provide lubrication for the blade.

The guide arms of the machines are generally free of vibration, increasing the accuracy of the cut while reducing noise. A small, easy to grip handwheel is used for fast and accurate blade tensioning. Depending on the model, there are mechanical stops for weights between 900 kg and 1,200 kg. Rusch manual bandsaws are usually energy-efficient through precision roller bearings and flywheels that keep rotational speed smooth-running and evenly balanced.

Many Rusch manual bandsaws feature a simple lever and lock mechanism, ensuring the cutting at mitred angles is reliable and accurate. Some bandsaws can make angled cuts ranging from 0° up to 60° while some can also cut at -60°. Most models feature an eccentric arc pin that uses two spherical roller bearings. These compensate for any misalignment or impact when cutting heavy materials at moderate speeds. Some models feature adjustable, pre-aligned bearings and interchangeable WIDIA plates for ideal compatibility when cutting a variety of materials.

The guide arms of Rusch manual bandsaws are constructed for reliability and strength. They are resilient to vibrational pressures, enabling them to keep their shape even over prolonged use. At SawsUK, we can supply manual Rusch bandsaws that operate at speeds from around 30 metres per minute up to 80 metres per minute.

Rusch Semi-Automatic Bandsaws

Semi-automatic bandsaws are usually activated by the operator pressing a button to begin the automated processes. This prompts the material clamp to lock into place. Once the blade is moving, the bow lowers at the correct down feed speed. Once cutting is complete, the bow returns to its starting position. This type of bandsaw is often used for medium volume batches where accuracy and speed is a priority.

Typical Features of Rusch Semi-Automatic Bandsaws

Rusch semi-automatic bandsaws typically offer a higher level of sophistication and versatility compared to a Rusch manual bandsaw. Generally, they can cut a variety of three-dimensional components including metal tubes with diameters of between 200 mm and 800 mm.

Semi-automatic bandsaws from Rusch usually include hydraulic bow lifting, descent and clamping. Some selected models may offer both hydraulic and manual clamping.

The semi-automatic bandsaw may include a facility for making two-speed cuts. Other versions of the machines feature a potentiometer that can alter the cutting speed while the blade is in operation.

Computerisation is a key feature of the Rusch semi-automatic bandsaws. They include an innovative microprocessor developed by Rusch's in-house technological experts. It provides greater control over multiple functions, from manual use to controlling cutting angles, sizes and speeds. An electronic display and control panel provide accuracy and clarity when making adjustments. Diagnostics are also included in the systems of some models for continuous operation.

The semi-automatic collection offers a high degree of versatile manoeuvrability. Some machines include swivel bases and table rotation. Linear ball recirculating guides with reinforced steel rails increase the bandsaw’s weight bearing capacity along its axis. They help provide superior precision during cutting.

A useful feature on many of the models in this category is a valve that regulates the blade's pressure during cutting. It ensures less robust, thin tubes or profiles are cut cleanly without distorting them. This handy feature helps prevent waste and saves time through cutting accurately from the start. A mist spray for reliable, continuous cutting is included as standard on some models, but as an optional extra on others.

The Rusch manual bandsaw range is also available with additional safety measures, including features such as a key lock to ensure only authorised personnel can operate the bandsaw. Machines usually stop automatically in the event of a blade breaking. However, many models include automatic cleaning of the blade to help maintain a free-flowing operation. Whenever the electronic system detects the bandsaw is no longer being used, it automatically closes the pump that supplies lubricating oil to the blade.

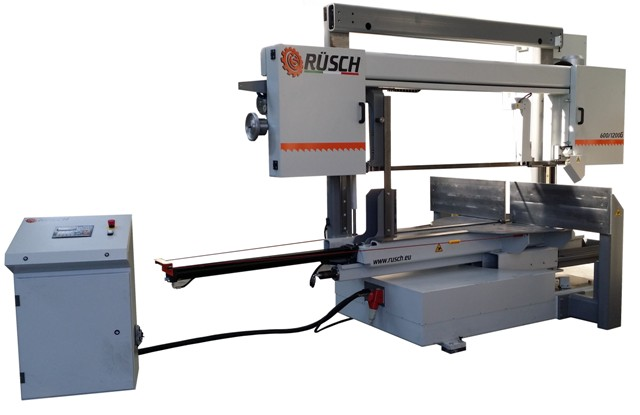

Rusch Fully Automatic Bandsaws

Automatic bandsaws offer the ultimate in cutting technology. They are usually programmable and require little or no supervision. They continue to automatically perform cuts until the pre-set number of components has been reached. The Rusch fully automatic bandsaw is an ideal solution for large businesses where production needs to be maintained at full capacity.

Our selection of Rusch fully automatic bandsaws includes truly advanced models that incorporate the latest in manufacturing technology. They can usually cut tubes, bars and multi-faceted, three-dimensional components measuring up to 1,160 mm in size. These bandsaws are manufactured in a robust, double column design that is perfect for the heaviest manufacturing and fabrication demands. They cut through a wide range of materials including plastics and metals such as mild steel, aluminium and stainless steel alloys.

Typical Features of Rusch Fully Automatic Bandsaws

These premium Rusch cutting machines incorporate Computer Numerical Control (CNC). It includes an onboard computer, which can be programmed via the 10" touchscreen control panel. Once basic details such as sizes and materials have been entered, the AUTOSAW software dictates every part of the cutting process. It's ideal for adding the highest level of independent automation in any medium or large manufacturing business.

Rusch CNC bandsaws are feature packed and include carriages with linear beams, ballscrews and brushless motors. They provide an exceptionally smooth-running operation with reduced friction, even when cutting for an extended time at high speed. On some machines the feed carriage may be up to 3,000 mm, making them ideal for the largest and heaviest cutting tasks. The machines themselves are particularly robust, with some models weighing as much as 135,000 kg. These are quality manufactured machines that are built to last.

Advanced bandsaws usually include enhanced features such as blade deviation detection and automatic realignment. It ensures every cut is uniform and highly accurate, which is particularly beneficial when processing large batches. CNC bandsaws typically include an easy, simplified method of changing the blades.

This category of bandsaw is mainly suitable for prolonged, heavy use, but it can also be useful for more delicate tasks which makes these saws versatile for a range of applications. A reduced pressure facility when clamping and cutting vulnerable structures or materials provides a superior, accurately finished edge.

Safety features generally include the machine automatically stopping if the blade should happen to break. The system can also detect if the bandsaw is no longer active. In this instance it immediately closes down the hydraulic pump that supplies the blade with a lubricant from the cooling tank in the machine's base.

Some fully automatic Rusch bandsaws are suitable for accommodating a range of versatile extras. These include vertical rollers, spray misting and a zero detect laser. A useful attachment that saves time and energy is a specially adapted vice for cutting components in multiple bundles.

Cutting metal produces substantial volumes of swarf that can obstruct the blade or the machine. However, Rusch CNC bandsaws generally include a swarf conveyor. It has a range of speeds and includes a brush for automatically cleaning the bandsaw blade.

Find Your Perfect Rusch Bandsaw

Rusch has a long, illustrious history in manufacturing precision engineered cutting machines, and at Saws UK you can find an extensive selection of the latest Rusch bandsaws. Whether you choose a manual, semi-automatic or fully automatic bandsaw, you'll benefit from a range of practical, innovative features providing superb cutting accuracy for every application. Every model benefits from decades of experience, expertise and product development from the experts at Rusch.

As one of the UK’s leading bandsaw experts, our knowledgeable team can help you find the perfect Rusch bandsaw for your requirements and will be more than happy to answer any queries you might have.

Share this post: