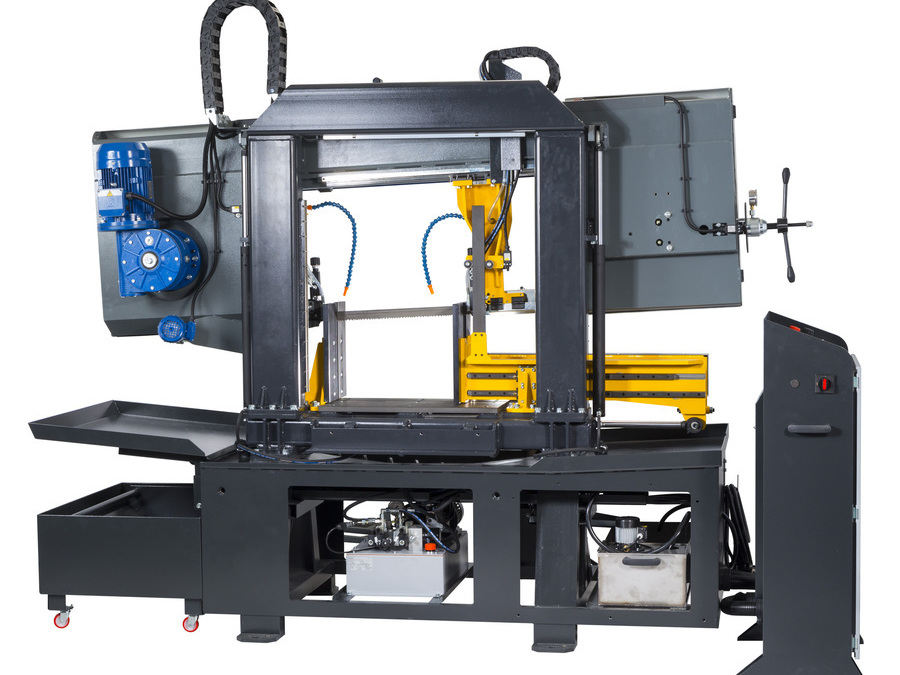

Alligator HD520 DC CNC

The robust, fully automated bandsaw with CNC control finds general application in the industrial division of large series even in the most difficult and non-stop operations, which also applies to heavy workpieces of large cross-sections. The extremely strong construction of the arm of the saw band, in combination with its massive two-column mounting on linear guides, guarantees excellent rigidity of the entire system and precise cutting. The industrial saw band 41 x 1.3 mm is produced in many variants and enables the cutting of a wide range of materials, including stainless steel or tool steel.

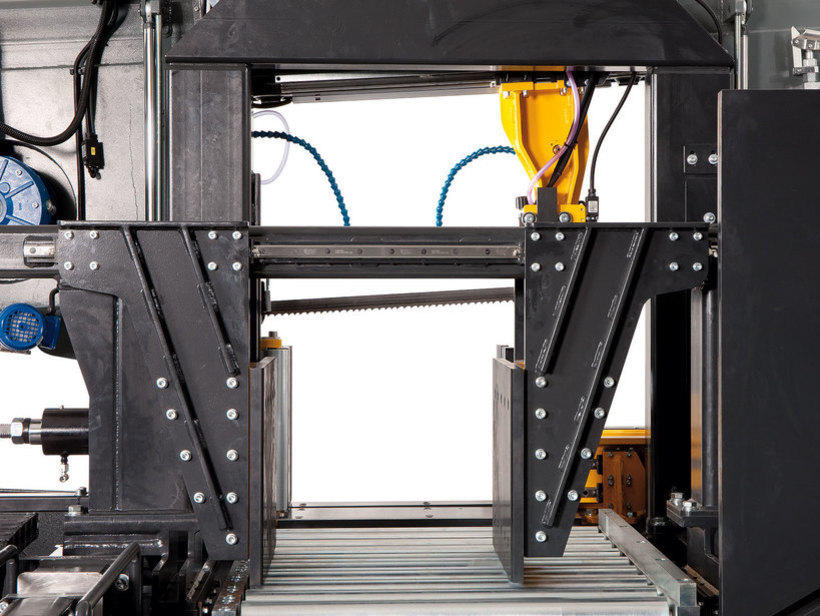

The machine is equipped with material feed using an industrial servo drive (servo motor with planetary gear). The servo drive together with the ball screw enable high speed and maximum accuracy of feeding the material, even with multiple feeds when cutting longer pieces. The possibility of setting three feed speeds (27, 42 or 50 mm/s) according to the weight and length of the divided material. The maximum length of a single delivery is 600 mm.

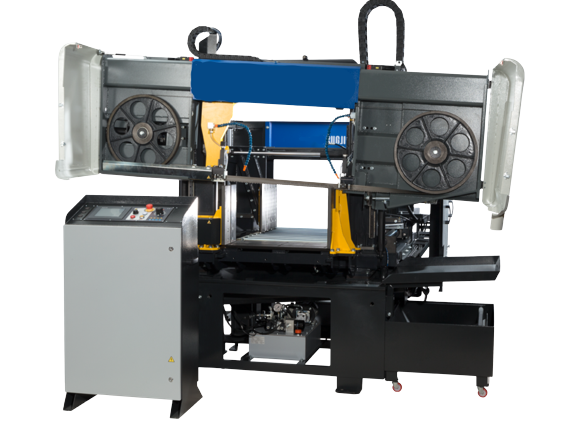

The central control panel with a large color touch screen (7.5") guarantees simple, intuitive control of all machine functions. The control unit enables the programming of up to 60 programs for quick setting of the required length of delivery during repeated production. Each program can be provided with a note, e.g. drawing number. There is also the possibility of programming and cutting a different number of pieces of different lengths without the need for additional machine operation. The machine can be operated in fully automatic, semi-automatic or manual mode.

Optimal clamping of the material during the cut is ensured by a full-stroke double-jaw vise that clamps the material before and after the cut and moves on linear guides. The hydraulic unit allows setting the necessary clamping force of the vise. Both guide blocks of the saw band are equipped with automatic regulation of pressure into the cut, which significantly speeds up and makes the cut more precise and increases the service life of the saw band.

The machine is equipped with a massive screw conveyor as standard. Its location directly under the cut ensures optimal chip evacuation. Chips can be drained into a metal container with a removable drip pan (accessory). High-quality lighting of the work space is ensured by a powerful LED strip with a cover. Behind the cut, the vise can be equipped with a support roller for splitting long pieces or a slide of material for short pieces.

In order to achieve maximum accuracy of material feeding and cutting accuracy, the machine is only intended for perpendicular cuts.

The very robust construction of the machine, made up of massive welds, guarantees the absorption of vibrations.

The large diameter of the impellers and the precise three-sided carbide guide guarantee the long-term life of the saw band and the precision of the cut.

Easy intuitive operation with ergonomically positioned controls on the central control panel.

Oversized storage of the impellers, tension wheel system and all rotating parts increases the long-term life of the machine.

The silent and maintenance-free drive of the saw band is provided by an industrial electric motor with a worm gear.

The machine is connected to a complete cooling system with a powerful pump and the possibility of separate flow regulation on both guide blocks and two other adjustable outlets. The emulsion bath with a powerful pump is located in the base of the machine.

Checking the saw band for proper tension or breakage. When the saw band breaks, the machine switches off automatically.

All pictures shown are for illustration purpose only. Actual product may vary due to product enhancement.

Standard Equipment

Frequency converter

Electrical cleaning brush

Steel circular brush

Pressure regulation

Screw chips conveyor

Rinse spray gun

LED Light

Optional Extras Available

Material chute

Oil mist lubrication

Laser alignment

Hydraulic tensioning

Saw band tension indicator

Signalling beacon M2

Green light

Red light

Additional rollers

Bevel gearbox with 5,5 kW motor

Chip container

Chip separator

Magnetic chip separator

|

Max Capacity |

Round 90° Square 90° Rectangle 90° |

520mm 500mm 700x480mm |

|---|---|---|

|

Operation |

Fully Automatic CNC Bandsaw |

|

|

Blade Size |

|

5770x41x1.3mm |

|

Main Motor |

Power |

400V/50Hz/4kW |

|

Pump motor |

Power |

400V/50Hz/0.12kW |

|

Hydraulic motor |

Power |

400V/50Hz/1kW |

|

Blade speed |

Variable |

15-90 m/min |

|

Vice Height |

Height |

920mm |

|

Hydraulic system oil |

Oil Type |

approx 26L ISO 6743/4-HM DIN 51 524 part 2-HLP |

|

Coolant tank |

Litres |

approx 35L |

|

Dimensions LxWxH |

|

3190x2570x2450mm |

|

Machine weight |

KG |

3100kg |

Blades for this machine are available here

Carriage is £12+VAT or Free for orders over £125+VAT. We accept paypal or credit and debit cards.

All Enquiries

Saws UK: Providing you with the right saw for the right purpose. We commission and we service. All backed up with a 10 Year warranty*