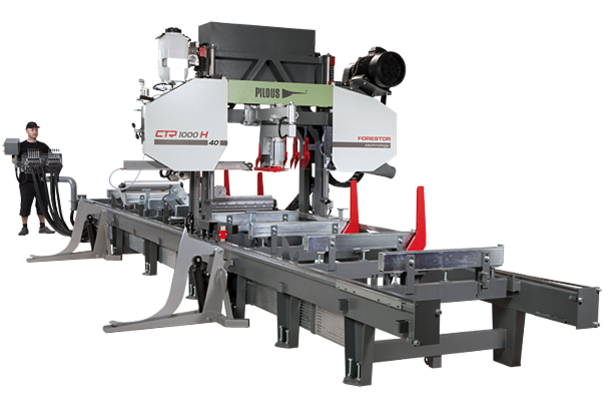

Forestor CTR 1000 H / 40

A new version of the legendary CTR 950 Hydraulic with increased maximum cut diameter of the log to 1000 mm.

Besides a completely new design of the machine there have been made a number of technical modifications and changes to improve the quality, user comfort and durability of the machine. Exceptionally robust construction of the machine and high-performance hydraulic equipment allow operation even under the most difficult operating conditions including non-stop operation. Many hydraulic accessories easily handle even very large logs, significantly increase the productivity of the machine and save labour costs.

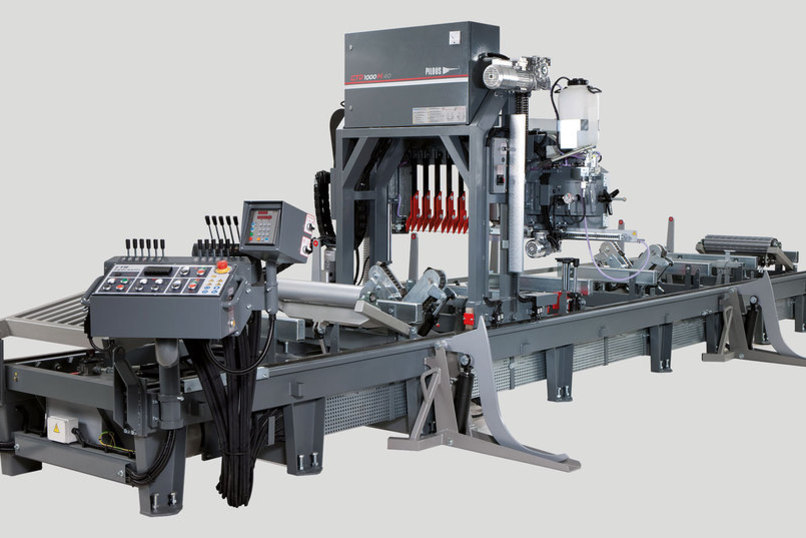

The basic version is fitted with the following accessories

Hydraulic log clamp - 2x

Tilting angle - 5x

Retractable log turner - 1x

Taper conicity passive roller - 1x

Taper conicity driven roller - 1x

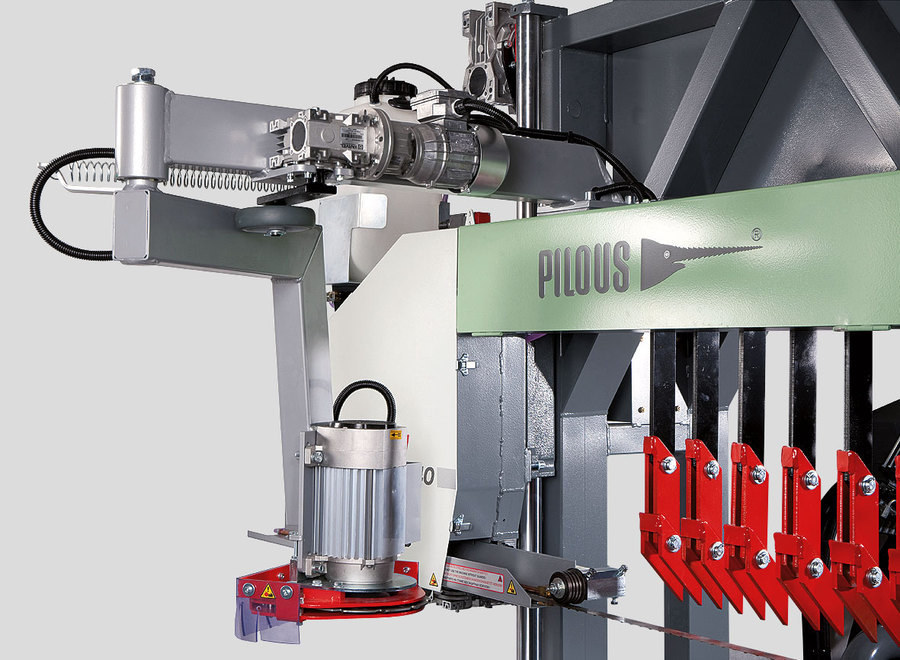

Thanks to the unique modular design of CTR series the machine is fitted with many fitting points for hydraulic equipment. That allows large variability of its placement with regard to the total cutting length and specifics of the processed material.

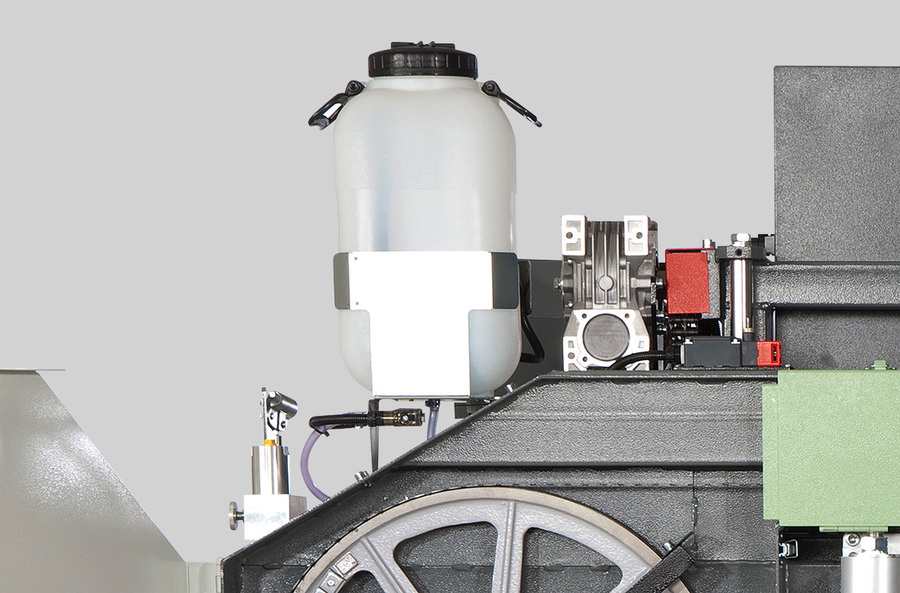

A wide, exceptionally massive running bridge of the saw band arm and robust running sections ensure undisturbed operation when cutting and even at high running speeds. Professional execution of all main technical units, such as running wheels with their bearing system, saw band arm construction, powering and feeding system, etc. ensure maximum service life and machine accuracy even under the most difficult operating conditions.

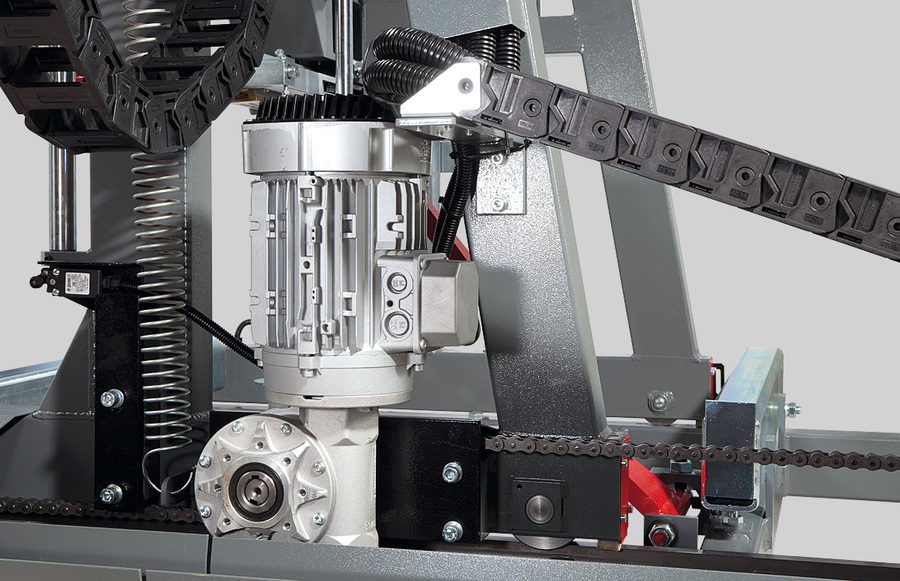

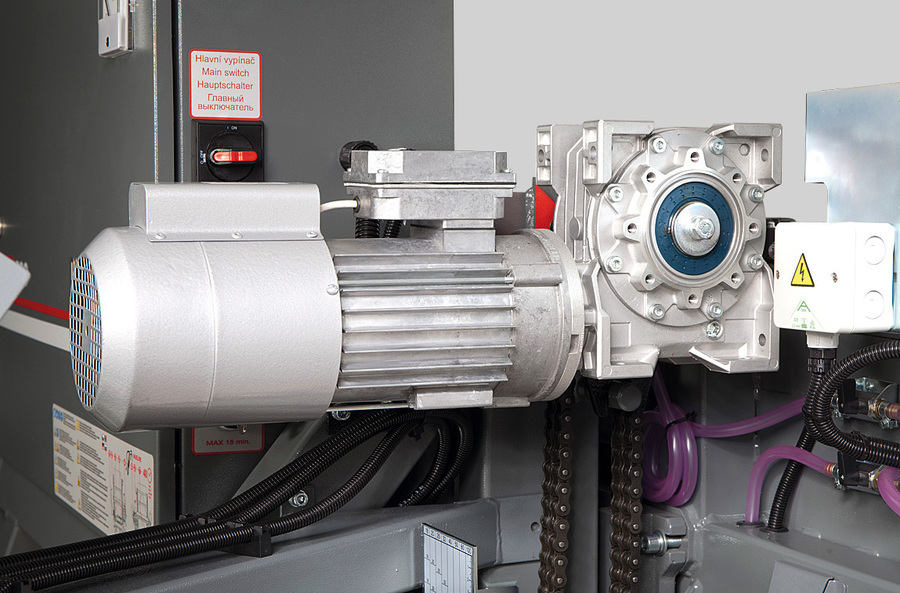

Continuously adjustable machine feed into the cut and back and saw band arm height adjustment. Travel speed is dis-played on the digital display. The central control panel is stationary and it’s placed on the main running section. This allows convenient machine control from a single place with complete hydraulic accessories. The feed into the cut and back is driven by an electric motor with worm gearbox controlled by a frequency converter. You can change the speed of travel simply by turning the potentiometer on the control panel. The end stops provide automatic deceleration and stopping in end positions.

The massive saw band arm is borne on adjustable hard-chromium rods (for moving up and down) which ensure absolute accuracy of saw band arm movement and virtually unlimited service life, if the machine is lubricated regularly. The vertical movement of the arm is provided by double-sided synchronous chain transmission powered by an electric motor with worm gearbox. The movement controlled from the central panel has two modes of speed – rapid feed and slow feed for accurate movement to a desired position. This system can be always additionally equipped with electronic metering which automatically moves to the specified position.

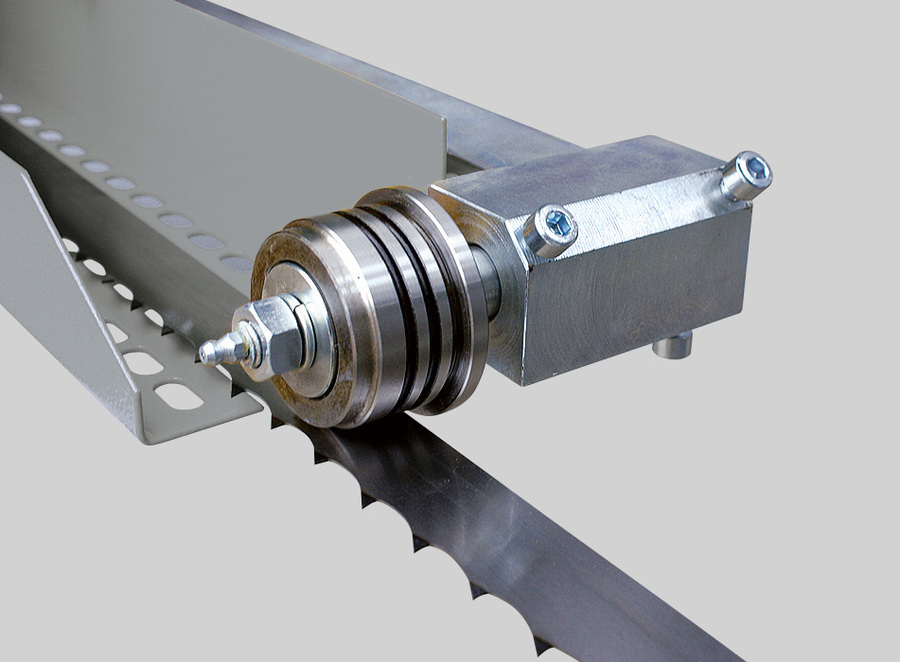

The arm is fitted with running wheels made of high-quality grey cast iron with accurate balancing against vibrations.

The wheel has a groove along its circumference. The groove holds a replaceable rubber-textile belt which creates an optimum contact area between the wheel and the saw band.

The sturdily mounted running wheel is powered through a wedge belt by a professional electrical motor specially balanced against vibrations. The tensioning wheel system moves along a sturdy cast iron wedge guide with adjustable pressure bar, which allows highly accurate adjustment without any free travel even in long-term machine operation.

The basis of the machine is formed by extremely stable travel sections with reversible, adjustable, steel guidance of the arm bridge. Travel sections are amply dimensioned for the indicated maximum diameters of processed logs and based on practice they count even with very tough operating conditions. Double sided guidance of a bridge on the travel section combined with a powerful engine, enable fluent and fast shift (removal) of even heavy cut pieces when using the cut material feeder. Length of the cut is practically unlimited for all types according to the number of installed sections. Travelling sections are equipped with massive, height adjustable timber bearing areas.

CTR series present the latest trends in construction of log saw bands with a special emphasis on maximum accuracy and long-term service life of the machine while ensuring minimum costs. The machines are designed in an original modular execution which allows easy replacement or adjustment of all main technical sections and their individual parts. This in the long-term perspective reduces the maintenance costs and service times and therefore production stoppages as well.

|

Max. log diameter |

1000 mm |

|---|---|

|

Max. opening betwen blade guides |

850 mm |

|

Min. blade height from support beam |

875 mm |

|

Min. log height |

30 mm |

|

Max. depth of cut |

450 mm |

|

Max. log length (standard model) |

7,6 m |

|

Length track section |

3 m |

|

Min. log length |

1,2 m |

|

Saw blade motor |

15 (18,5) kW |

|

Horizontal feed motor |

1,5 kW |

|

Vertical feed motor |

0,55 kW |

|

Hydraulic motor |

5,5 kW |

|

Hydraulic oil |

ISO 6743/4-HM, DIN 51 524 part 2-HLP |

|

Sawblade |

5350 x 35 - 40 x 0,9 - 1,1 mm |

|

Weight (standard model) |

2580 kg |

|

Weight (track section) |

420 kg |

Nomimal current of circuit breaker is minimally: main el. motor 15,0 kW – 50 Ampere / main el. motor 18,5 kW – 63 Ampere

All Enquiries

Saws UK: Providing you with the right saw for the right purpose. We commission and we service. All backed up with a 10 Year warranty*