ALLIGATOR XPERT 3.0 3D BANDSAW

3D Cutting Bandsaw

THE BAND SAW IS THE FASTEST, CHEAPEST AND MOST EFFICIENT SOLUTION FOR SEPARATION OF 3D PRINTED METAL PARTS FROM THE PRINT BOARD.

The single-purpose two-column band saw guarantees fast and accurate separation of the product from the 3D printer from the printing plate. Cutting accuracy 0.1 mm, cutting width 1.5 mm.

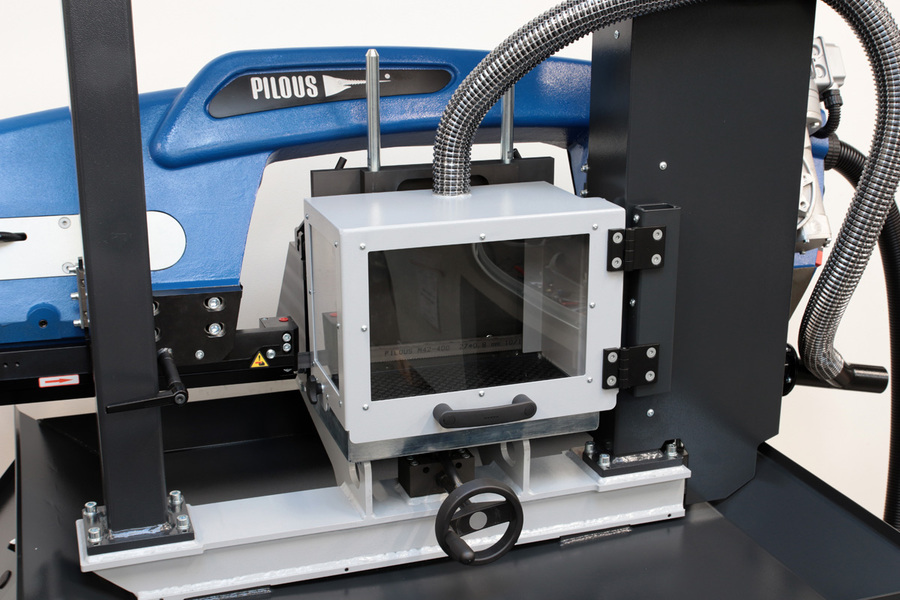

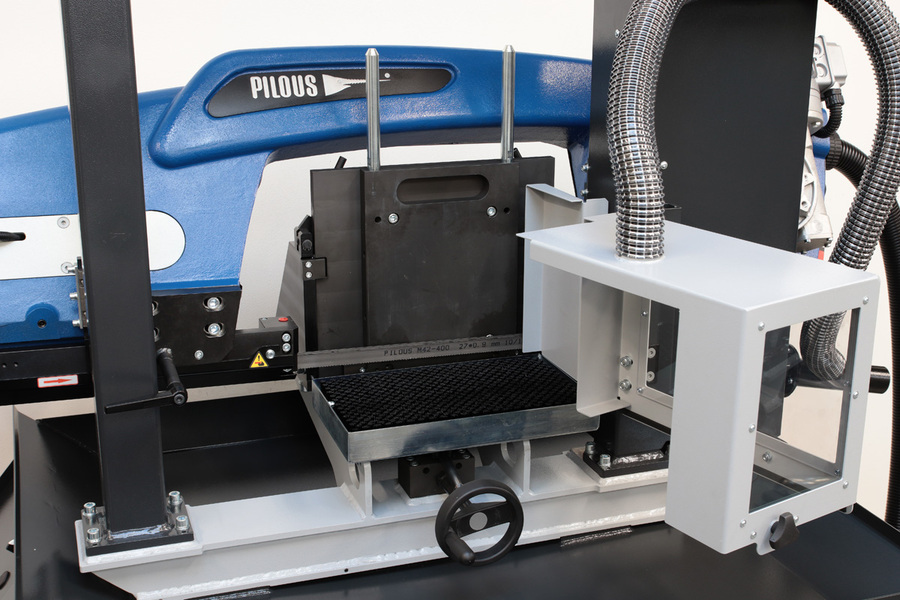

A special, adjustable clamping system of the printing plate guarantees its optimal clamping. It is equipped with a folding mechanism with stops. This enables easy and quick attachment of the printing plate in a horizontal position and simple folding into a vertical working position. The precise clamping of the printing plate guarantees the setting of the cut with minimal additions, thus saving material during printing. The distance of the cut from the printing plate can be set very easily manually with the control wheel.

The maximum size of the printing plate is 300 x 300 mm, we will adjust the spacing and diameter of the threads according to your requirements.

The continuously adjustable jaw of the clamping system enables the installation of a printing plate with a thickness of 10-60 mm with the possibility of mechanical adjustment up to a range of 0-70 mm.

In the standard version, the jaw of the clamping system is prepared for holding a printing plate measuring 250 x 250 mm.

The board can be attached in two ways:

Using screws, standard thread spacing 210 x 210 mm. In the jaw of the clamping system, these threads are solved by exchangeable inserts, so it is possible to choose the size of the thread according to the diameter of the screw hole in the printing plate, M5, M6 and M8. The insert is also replaceable in case of thread damage.

Using the quick-clamping system, very simple clamping by tightening one screw. The quick-clamping system can be adjusted to the size of the printing plate according to your requirements.

The machine is installed on an innovative base, during the construction of which emphasis was placed not only on sufficient stability, but also on the smallest possible size (the width of the base is only 700 mm) and the possibility of simple removal of chips into the removable magazine.

High-quality lighting of the work space with a powerful LED lamp.

A completely new concept of saw band arm casting and a unique design. The massive cast iron arm is quite exceptional in the category of two-column band saws. This, in combination with the massive two-column support of the arm, moving on linear guides, guarantees excellent rigidity of the entire system and a precise cut.

An industrial Bi-metal saw band of size 27 x 0.9 mm is used as a cutting tool. The precision of the saw band cut is guaranteed by the three-sided carbide guide before and after the cut. The possibility of setting the optimal speed of the saw band using a frequency converter in the range of 20-130 m/min. contributes to the achievement of maximum cutting productivity, which significantly contributes to the accuracy and speed of cutting and the service life of the saw bands.

The arm of the saw band moves on linear guides using a hydraulic cylinder driven by a powerful hydraulic unit. Simple control on the central control panel and continuously adjustable cutting speed. After finishing the cut, the saw band is automatically switched off and the arm moves up to its original, adjustable position.

The machine is characterized by an overall very robust processing. The basis is a stable base of the machine with a clamping system of the printing plate and a system of two-column storage of the arm. The unique arm of the saw band is equipped with cast iron wheels with massive bearings, driven by an industrial motor with a worm gear. All this guarantees long-term cutting accuracy and machine life.

All Enquiries

Saws UK: Providing you with the right saw for the right purpose. We commission and we service. All backed up with a 10 Year warranty*