The Best Bandsaws For Cutting Different Materials

Selecting Bandsaws for Material Type

Choosing the best blade depends on compatibility. You need to match the blade itself, its size and tooth design to the material you are about to cut. In general, the following principles apply:

Bandsaws For Metal

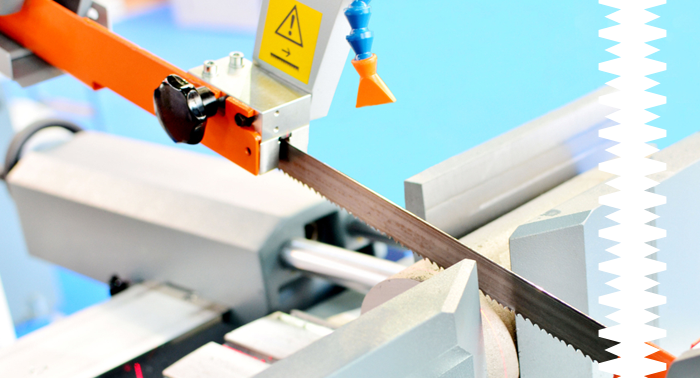

Bandsaws for cutting metal are available in a number of options, ranging from simple chop saws to fully automatic bandsaws for commercial applications.

Blades used in metal cutting bandsaws usually have smaller teeth with narrow gaps between them. They are usually reliably strong and highly durable, producing well-defined, even cuts.

Bandsaws For Wood

Wood cutting bandsaws are designed to enable fast, highly precise cuts including mitres and can be used on a range of wood types.

Blades designed for cutting wood typically have widely spaced, large teeth. They help rough fibres and moist wood pulp slip easily from the blade, preventing it from becoming blocked.

Bandsaws For Plastic, Ceramic And Fibreglass

Bandsaws for plastic are designed to enable a range of plastics and composites to be cut accurately and cleanly. They are essential in many fabrication, production and commercial settings for cutting plastics in a variety of shapes, sizes and densities.

When cutting these materials, you should benefit from using a blade with a grit edge. It produces a fine, even cut, reducing the risk of such materials splintering or tearing.

Multi-Purpose Bandsaws

When using a blade that's specifically designed for a particular material, it might not be the best practice to use it on an alternative. For instance, cutting metal with a blade designed for wood often results in a poor finish and may even cause work to be scrapped. It can be time-consuming to continually change bandsaw blades, particularly for small quantities. However, depending on the materials you wish to cut, you can improve efficiency by choosing a machine and blade that can cut through a variety of different materials.

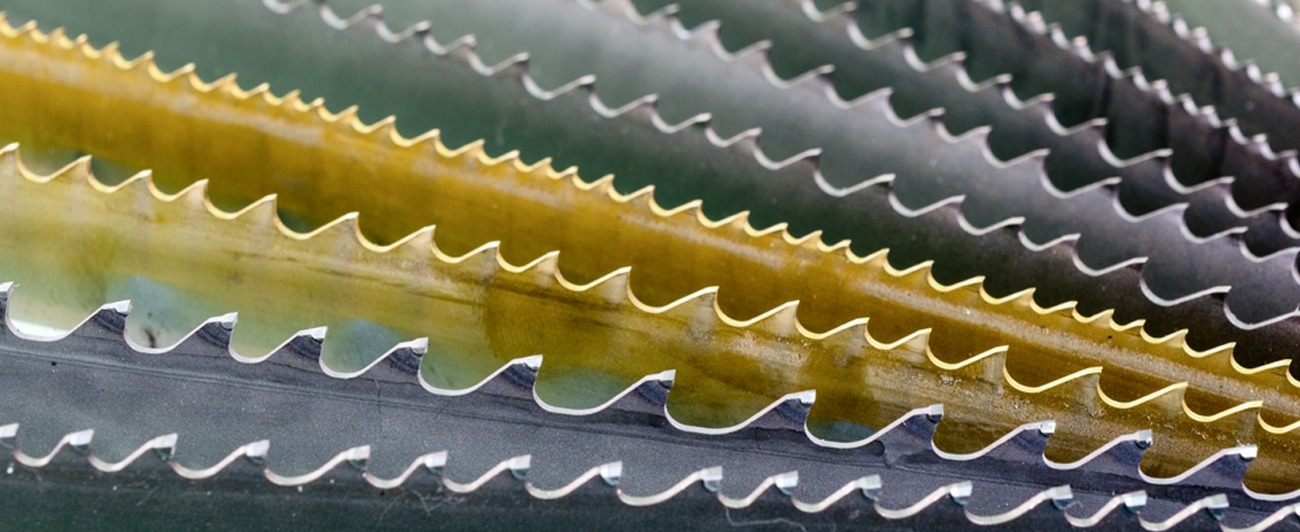

Types Of Bandsaw Blades

Using the right type of blade for the type of material you need to cut is essential for achieving a clean, precise cut. It’s also important to use the correct type of blade for safety reasons. Our premium quality blades are manufactured to the highest specifications to provide reliable, high performance cutting. The materials they are made from usually make them suitable for particular sawing projects.

Carbon Steel Bandsaw Blades

This is a reliable, general purpose blade. It is usually heat treated for increased strength and durability. It's available in many tooth sizes and densities, providing an excellent match for many different materials. A typical size blade is 114"/13/6tpi.

Ideal for Cutting:

Steel, stainless steel, mild steel and non-ferrous metals such as zinc, brass, lead and bronze. A carbon steel blade can also cut plastic, paper, wood, foam, rubber and cork.

Bi-Metal Bandsaw Blades

As a premium grade saw, this blade offers superior strength and resilience. During manufacture, the blade of spring steel incorporates a hardened edging of high-speed cobalt steel that provides an effective, long-term cutting performance. At SawsUK, we stock bi-metal blades in lengths beginning at 60" (1524 mm) lengths and widths of 1/4" (06 mm).

Ideal for Cutting:

All types of structural metal. They are excellent bandsaws for material shape including three-dimensional structures. The bi-metal blade should effortlessly saw through pipes, tubular metal, H-beams and angled sections.

Ground Tooth Bandsaw Blades

When sawing high volume batches, the ground tooth blade is an efficient choice. Manufactured through a combination of precision engineering and innovative technology, this blade is strong and remarkably resilient. It can withstand the intense heat that's produced when sawing continuously at high speed. At SawsUK, we have a wide range of ground tooth blades in many sizes and configurations.

Ideal for Cutting:

Metals of all descriptions including stainless steel, carbon steel, aluminium and copper.

Carbide Grit Edge Bandsaw Blades

When you need a versatile bandsaw blade that can cut a wide range of diverse materials, the carbide grit edge blade is an excellent choice. It's highly reliable, producing a fine cut finish with minimal resistance even when sawing abrasive materials.

Ideal for Cutting:

Metals such as hardened steel, cast iron, titanium and nickel-based alloys. The blade can also be used to effectively saw fibreglass, graphite, concrete or brick tiles, wire cables and car tyres.

HSS-DMo5 Circular Saw Blade

This blade is manufactured from a high-speed steel alloy incorporating tungsten, molybdenum and vanadium. The metal produces a strong blade with outstanding mechanical properties and superior hardness up to 65 ± 1HRC. The blade is steam-treated to ensure it has an extra fine surface that significantly reduces friction.

Ideal for Cutting:

Mild steel, stainless steel and structural steel such as pipes and H-beams. This blade can also cut metals such as brass and copper.

TCT Circular Saw Blade

The tungsten carbide tipped (TCT) blade is exceptionally long-lasting. It can also withstand the extreme heat produced while operating at high speed. This type of blade usually starts at a size of 400 x 32 x Z=120 TCT.

Ideal for Cutting:

Metals such as titanium, zirconium, nickel and cobalt. It also effectively saws pipes and rails, plastic, wood, bricks, tiles and concrete.

TiCN Blade

This blade is coated with titanium nitride to provide additional strength and durability

Ideal for Cutting:

Specially hardened metals including stainless steel, copper alloys and titanium alloys.

Bandsaw Blades For Cut Type

Once the material of the blade for your bandsaw or circular saw has been selected, you need to consider the type of cut it should produce. In general, small evenly-spaced teeth are more suitable for metal, while wide spacings are ideal for wood. There are several teeth formations and cuts with each one usually more compatible with specific materials.

Choosing Bandsaws for Three-Dimensional Profiles

When cutting structural steel with a bandsaw, a suitable choice would be a bi-metal blade with a structural tooth arrangement (S42 Alligator Bandsaw Blade).

BM42 Alligator Bandsaw Blade would provide excellent results for most metals, plastics, or wood as well as many other materials. SAWS UK stocks a wide range of blades to suit bandsaws and circular saws.

Bandsaws & Blades For Size

Generally, when cutting curves, narrow blades produce tighter angles. The less teeth a circular saw blade has, the faster it operates.

Bespoke Bandsaws for Unique Projects

When you need a replacement blade, we have a wide range in many sizes and configurations to suit any sawing task.

However, if you can't find the exact bandsaw or circular saw blade you need for your latest project, contact SAWS UK directly. We offer a made to measure service to ensure you find the perfect cutting tool.

Tagged as: Bandsaw Machines

Share this post: