Bonetti Bandsaws Brand & Product Guide

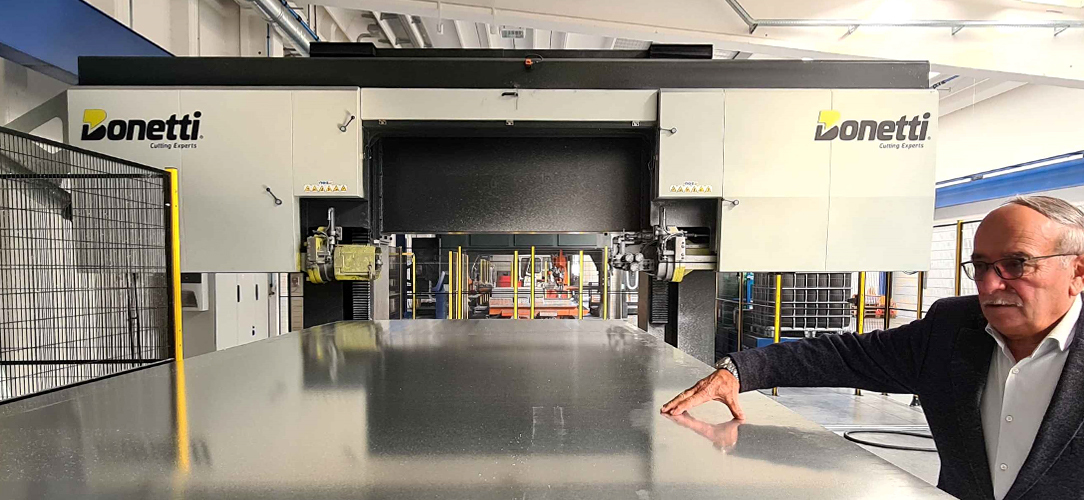

Bonetti Group, founded in 1979, is a globally recognised brand specialising in machines and cutting solutions, particularly bandsaw machines for ferrous and non-ferrous materials. Known for their superior quality and innovation, Bonetti bandsaw machines stand as a testament to Italian engineering prowess.

The company began its operations by initially producing heavy industrial assemblies and parts for steel industries before it started manufacturing bandsaw machines under the OPUS brand name in 1990. Bonetti bandsaws are celebrated for their cost-effectiveness, offering a fast return on investment due to their low cost per cut, which is one of the reasons Bonetti is a leading name in the market .

About Bonetti Cutting Machines

Hailing from Italy, Bonetti has carved out a niche for itself in the manufacturing sector with its high-quality cutting machines. The brand prides itself on creating products that not only cater to the needs of the industry but also push the boundaries of what is possible. As a result, these machines are renowned for their precision, durability, and cutting-edge technology.

Their commitment to quality and innovation is reflected in their rigorous design and manufacturing process. Each Bonetti machine undergoes extensive testing to ensure it meets the highest standards of performance and durability. This unwavering commitment to quality has made Bonetti a trusted name among professionals in the industry.

Key Events In Bonetti’s History

The Bonetti story began in 1979 when the firm embarked on a journey to reshape the landscape of bandsaw machines. A pivotal moment arrived in 1990, when the brand acquired the knowledge of the OPUS metal brand, broadening their horizons and enhancing their technical capabilities.

This strategic move would set the stage for the innovative steps Bonetti would take in the years to come.

In 1994, Bonetti reached a significant milestone when it developed new models and produced the first high-speed sawing machine for aluminium plates. This marked a substantial achievement for the brand, demonstrating their capacity for technological innovation in catering to the industry's evolving demands.

The dawn of the new millennium saw Bonetti attaining the prestigious ISO 9001 certification in 2000. This achievement represented the company's commitment to quality management and consistent performance, bolstering their credibility and customer trust.

In 2015, Bonetti celebrated a significant achievement of installing 2000 unique machines worldwide, cementing their global footprint. The same year, they broadened their reach further by opening an office in Moscow, signalling their global ambition and dedication to serving customers internationally.

The subsequent years saw an expansion in Bonetti's operational capacity. In 2016, the company embarked on a substantial expansion of their production area to a sprawling 13,000 square metres and invested in building new offices.

In 2017, Bonetti continued to push the boundaries of technological advancement by launching the 545 EVO ALU, a machine specifically designed for aluminium cutting. This meant that Bonetti offered the most comprehensive range of aluminium cutting machines in the market, and further solidified their position as a leader in the industry.

Bonetti celebrated four decades of success in 2019. The 40-year milestone signified the brand's longevity, reliability, and dedication to quality, marking an exciting chapter in their history and setting the stage for future innovations.

For Expert Advice

Bonetti Bandsaw Machines Range

When investing in a bandsaw machine, the choice of brand significantly impacts the performance, efficiency, and quality of your output. Bonetti, with its commitment to superior engineering and technological innovation, offers machines packed with features designed to deliver unmatched precision and durability.

Bonetti Steel Saws

Within the steel saws product line, Bonetti offers a wide range of models designed for different levels of cutting demand, each with distinct features. From compact models ideal for small workshops to heavy-duty machines capable of handling large production volumes, these specialists cater to a diverse set of needs.

This range includes various types of saws such as horizontal bandsaws, vertical contour saws, moving table saws, and heavy-duty saws. Each series within the range is designed with specific applications in mind, whether it's for handling heavy workloads, high-speed cutting of high tensile alloys, or providing versatility for a wide array of uses.

This comprehensive range of steel saws is a testament to Bonetti's commitment to providing robust and reliable solutions, which are amongst the best metal cutting bandsaws currently on the market.

What makes Bonetti’s steel bandsaw machines truly stand out are their unparalleled features. For instance, the advanced blade control system ensures optimum cutting speeds, which enhances efficiency and prolongs blade lifespan. This feature can be vital when dealing with diverse types of steel, ensuring that every cut is precise and clean, regardless of the material's hardness or size.

Other features include automatic blade tension adjustment for consistent results, and a sturdy construction guaranteeing longevity. From solid steel bars to thick steel plates, Bonetti's steel saws prove to be invaluable assets in any metalworking environment.

Bonetti Aluminium Saws

Recognising the unique challenges faced by bandsaws for cutting aluminium, Bonetti has developed a range of bandsaw machines tailored specifically for this material. The aluminium saws line of machines offers precision cutting for a wide range of aluminium forms, from thin sheets to large blocks.

In their aluminium saws range, Bonetti presents a variety of models, each designed to cater to different cutting requirements. Some models are crafted for high-speed, high-volume production, while others are designed for precision cutting of complex shapes.

High-speed aluminium bandsaws are designed for high-volume production, offering impressive cutting speeds and accuracy. These machines are well-suited to applications where large volumes of aluminium need to be processed quickly without compromising on the quality of cut.

On the other end of the spectrum, the brand produces precision aluminium bandsaw, designed for intricate and complex cuts. These machines offer exceptional control and precision, making them ideal for applications that require detailed and complex shapes.

Features that make Bonetti's aluminium bandsaw machines stand out include high cutting speeds for efficient production, adjustable blade guides for precision cutting, and state-of-the-art cooling systems. The latter is particularly critical when cutting aluminium, as the material tends to generate substantial heat, which can affect the quality of the cut and the lifespan of the blade.

With Bonetti's aluminium saws, users can confidently tackle any aluminium cutting task with precision and efficiency.

Bonetti Specialised Saws

Bonetti’s mission to provide precise, reliable, and durable cutting solutions extends well beyond standard applications. Recognising the unique needs of different industries, the brand has channelled their technological know-how into creating specialised bandsaw machines.

Aerospace Industry

The aerospace industry has rigorous standards for quality and precision, given the critical nature of its components. Materials used in this industry, such as high-strength alloys and composites, require specialised cutting equipment to ensure accurate and clean cuts.

Recognising this, Bonetti has developed bandsaw machines specifically for the aerospace industry. These machines are equipped with features such as advanced cooling systems and high-precision blade guides, which ensure that cuts are clean, accurate, and free from deformation; a critical requirement when working with aerospace materials.

Moreover, these machines are designed to accommodate the large and irregularly shaped materials often used in this industry, offering flexibility and versatility.

Tyre Manufacturing

The tyre manufacturing industry presents its own unique set of challenges. Tyres are composed of a variety of materials, including rubber, fabric, and steel, each of which has different cutting requirements.

Bonetti’s bandsaw machines for tyre manufacturing are designed to handle these diverse materials effectively. With special blade types and an adjustable cutting speed system, these machines can smoothly transition between different materials, ensuring a clean cut regardless of the material composition.

This adaptability is crucial in tyre manufacturing, where precision and consistency directly impact the quality of the final product.

Aluminium Foundries

Aluminium foundries, where raw aluminium is melted and cast into various shapes, require specialised cutting equipment. The irregular shapes and large sizes of the aluminium blocks used in these foundries necessitate bandsaw machines with exceptional power and adaptability.

Bonetti has met this need with their range of bandsaw machines for aluminium foundries. These machines feature robust construction and high-powered motors, enabling them to handle large aluminium blocks with ease.

These impressive machines are equipped with features such as powerful cooling systems to prevent overheating, a common issue when cutting aluminium, and adjustable blade guides to accommodate irregular shapes.

For Expert Advice

Key Features Of Bonetti Bandsaw Machines

Bonetti bandsaw machines are equipped with a range of key features that elevate their precision, performance, and reliability, setting them apart from their competition.

Advanced Blade Control Systems

At the heart of Bonetti bandsaw machines lies their advanced blade control systems. These systems are designed to optimise cutting speeds based on the material being cut, ensuring the perfect balance between efficiency and precision.

By automatically adjusting the blade speed, Bonetti machines deliver consistent, clean cuts across a wide range of materials, including steel, aluminium, and composites. This feature not only enhances cutting accuracy but also extends the lifespan of the blade, resulting in cost savings for operators.

Automatic Blade Tension Adjustment

The range of bandsaw machines take the guesswork out of blade tension adjustment with their automatic blade tension adjustment feature. This innovative system ensures that the blade maintains optimal tension throughout the cutting process, guaranteeing consistent performance and minimising the need for manual intervention.

The result is improved cutting accuracy and reduced downtime, as operators can focus on their work without worrying about blade tension adjustments.

Robust Construction

Durability is a hallmark of Bonetti bandsaw machines, thanks to their robust construction. Crafted with high-quality materials and meticulous attention to detail, these machines are built to withstand the rigours of heavy-duty cutting.

The sturdy frames, precision-engineered components, and reinforced structures ensure that Bonetti machines can handle demanding tasks day in and day out, providing long-lasting performance and reliability for years to come.

High Cutting Speeds

Bonetti bandsaw machines are renowned for their exceptional cutting speeds, delivering impressive productivity gains for operators. Whether it's steel, aluminium, or other materials, the brand’s machines excel at swiftly and accurately slicing through them.

The ability to achieve high cutting speeds not only saves valuable time but also allows businesses to meet demanding production schedules without compromising on the quality of the cuts.

Adjustable Blade Guides

To achieve precise and intricate cuts, Bonetti bandsaw machines feature adjustable blade guides. These guides provide operators with the ability to fine-tune the cutting process, ensuring optimal blade alignment and minimising blade deflection.

The result is clean, straight cuts that meet the highest standards of accuracy, making Bonetti machines ideal for applications that require intricate shapes or complex cutting patterns.

Innovative Cooling Systems

Heat generated during the cutting process can impact the quality of cuts and potentially reduce blade life. Bonetti addresses this challenge with their innovative cooling systems. These systems effectively dissipate heat from the blade and workpiece, ensuring that the cutting process remains cool and consistent.

By maintaining optimal temperatures, Bonetti machines deliver superior performance, prolong blade life, and reduce the risk of material distortion.

Find The Right Bonetti Bandsaw Today

Whether you operate in a small workshop, large manufacturing facility, or need specialised cutting machines for sectors such as aerospace or fabrication, Saws UK has the perfect range of Bonetti bandsaw machines to cater to your specific needs.

These cutting-edge machines are engineered to tackle the toughest cutting challenges, delivering exceptional results in every operation. So, enhance your cutting capabilities, elevate your productivity, and unlock new levels of precision today at SawsUK!

For expert advice on finding the right bandsaw for your needs, get in touch with our expert team.

For Expert Advice

Share this post: