Bandsaw Training, Re-training & Commissioning

The bandsaw machine, a vital piece of equipment across a wide spectrum of industries, has evolved significantly since its invention in the 19th century. But with such great utility comes complexity; operating a bandsaw machine safely and efficiently requires an intimate understanding of the machine's workings, its potential hazards, and the techniques to leverage its full potential.

Regardless of the specific type of bandsaw—be it horizontal or vertical, metal-cutting or wood-cutting, comprehensive training is crucial. Proper bandsaw training equips operators with the knowledge and skills to not only safeguard themselves and others around them but also to streamline their work process, reducing costly errors and enhancing productivity.

Recognising the need for expert-led, comprehensive bandsaw machine training, Saws UK University was established. This valuable training experience allows operators to approach their work with heightened confidence, backed by a solid understanding of the task at hand.

Understanding Bandsaw Machine Training

Bandsaw machine training, at its core, is a comprehensive program designed to instil operators with the knowledge, skills, and techniques necessary to effectively and safely operate bandsaw machines. However, the depth of our training is what truly sets it apart, making it an invaluable asset for anyone involved in the use of these machines.

Getting To Grips With Bandsaw Machines

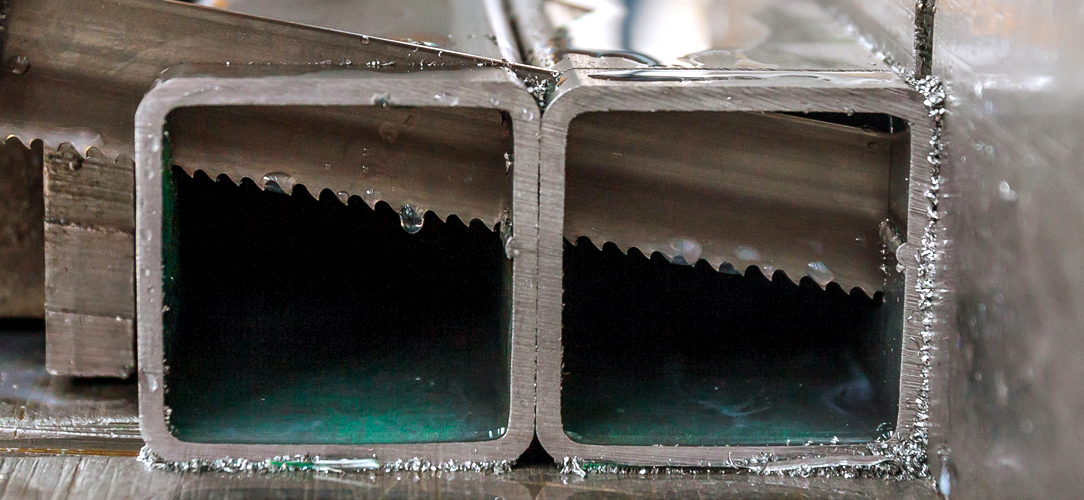

These powerful tools, capable of creating precision cuts through a variety of materials, operate on intricate mechanisms. Training spans from setting up the machine and preparing it for work, known as commissioning, to the actual operation, where different materials require specific techniques and considerations.

The training begins with a deep dive into the machine's architecture, exploring each part's function and interaction with the whole system. Participants are guided through the myriad components of the bandsaw- from the blade, guides, and wheels to the motor and the drive system. Understanding these elements is fundamental to operating the machine effectively and troubleshooting any potential issues.

Bandsaw Operators

But bandsaw machine training isn't just about the hardware; it's equally focused on the operator. One of the key elements of the training involves understanding the material being worked on. Different materials have different properties, and recognising these can significantly affect the efficiency and quality of the cut.

Bandsaws, while incredibly useful, can also be dangerous if mishandled. Proper training teaches operators how to handle the machine safely, recognise potential hazards, and adhere to safety regulations. By investing in bandsaw machine training at Saws UK University, you not only ensure your safety but also enhance your productivity.

Bandsaw Maintenance

Bandsaw machine training also emphasises the importance of regular maintenance. A well-maintained machine not only functions efficiently but also lasts longer, reducing downtime and repair costs. The training covers the essential maintenance routines, from simple tasks like cleaning and lubrication to more complex ones like blade replacement and alignment.

The training program provides a well-rounded understanding of the machine, the materials, and the techniques, turning operators into proficient users capable of getting the best out of their bandsaw machines.

Bandsaw Commissioning & Operator Training

The process of bandsaw commissioning sets the foundation for the successful operation of the machine. It is the initial setup, where the bandsaw machine is assembled, installed, tested, and adjusted to ensure it operates as efficiently and safely as possible.

Thorough Bandsaw Commissioning

Without a thorough and correctly executed commissioning process, operators could face numerous issues down the line, including poor performance, increased wear and tear, and even potential safety hazards. This is why bandsaw commissioning is an essential component of our training program at Saws UK University.

During the commissioning stage, trainees are guided through the process of assembling the machine, starting with understanding the basic configuration of the bandsaw. This includes familiarising trainees with various parts such as the table, band wheels, blade guides, and the blade itself. Assembling these parts correctly is essential to ensuring the bandsaw performs optimally and lasts as long as possible.

Installation of the machine is another key aspect of commissioning. This involves placing the machine in the designated area, considering factors like the power supply, floor condition, and space for safe operation. Trainees learn how to securely anchor the machine to the ground and connect it to the power source.

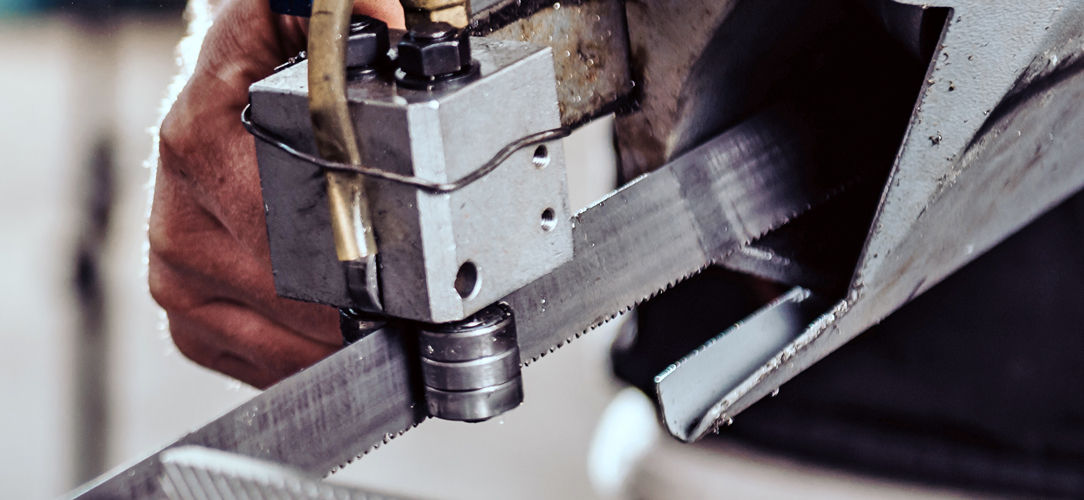

Once the machine is assembled and installed, the next step is testing and adjustments. Trainees learn how to conduct initial testing, checking for issues like blade tracking, blade tension, and guide alignment. They are taught how to adjust these components to rectify any detected problems- this process is critical for ensuring that the machine operates safely and cuts accurately.

Bandsaw Operator Training

Operator training, on the other hand, delves into the daily operation of the bandsaw machine. This covers everything from starting up the machine and setting the correct cutting parameters to executing cuts and shutting down the machine safely. In this stage of training, trainees are taught to understand the various controls of the machine, learning what each button, lever, and knob does, and when to use them.

Operator training also includes learning how to handle different materials. As each material has different properties, understanding how to adjust the machine's settings for each one is key to achieving clean, precise cuts. For instance, cutting through metal requires a slower blade speed than cutting through wood, and this adjustment is crucial to prevent blade wear and machine damage.

The outcome of Bandsaw Commissioning & Operator Training at Saws UK University is a proficient operator who understands not only how to use the bandsaw machine, but also how to maintain it, troubleshoot common issues, and ensure it operates at its maximum potential. The knowledge and skills acquired from this training translate directly to increased productivity, reduced machine downtime, enhanced safety, and ultimately, substantial time and cost savings.

The Need For Re-Training

Bandsaw machine re-training serves multiple purposes. First, it ensures that operators' knowledge and skills remain current, aligning with the latest developments in bandsaw technology and industry practices. This is important as even experienced operators may find themselves lagging behind if they do not keep up with these advancements.

Retraining provides the platform to learn about new features, tools, materials, and techniques, enabling operators to adapt their skills to the evolving demands of their roles.

Re-training reinforces the basic principles of bandsaw operation, providing a valuable opportunity for operators to refresh their foundational knowledge and skills. It is not uncommon for operators to inadvertently develop bad habits or forget certain procedures over time, and regular retraining helps to correct these issues before they become ingrained, promoting consistent adherence to best practices.

At Saws UK University, we recognise the importance of retraining and have incorporated it into our training framework. Our retraining sessions are tailored to the needs of the attendees, covering everything from basic refresher courses to advanced workshops focusing on new technologies or techniques.

This adaptive approach ensures that each retraining session delivers maximum value, enhancing operators' skills, and keeping them at the forefront of bandsaw operation expertise.

Bandsaw Safety Training

When it comes to operating heavy machinery like bandsaws, safety is not just a priority, it is a necessity. The potential risks involved in handling these powerful machines underscore the need for a robust safety training program. At Saws UK University, we firmly believe that an educated operator is a safe operator, and we place a strong emphasis on safety training as part of our comprehensive course offering.

Our safety training program focuses on educating operators about potential hazards associated with bandsaw machines and how to prevent accidents. This training spans a range of critical topics. First and foremost, it covers the safety features of the bandsaw machine itself. Understanding how these features work- such as blade guards, emergency stop buttons, and safety interlocks- is the first line of defence in preventing accidents.

Next, the training delves into the correct operating procedures. Following these procedures reduces the risk of accidents caused by improper use of the machine. This includes guidance on how to safely feed material into the machine, how to adjust the blade speed and tension, and how to correctly use the machine's controls.

Machine maintenance is another key aspect of our safety training. Regular maintenance checks can identify potential issues before they become hazardous. Trainees learn how to inspect their machines for signs of wear and tear, such as dull blades or worn out parts, and how to replace or repair these parts safely.

In addition to prevention, our safety training also prepares operators to respond effectively in the event of an emergency. This includes first-aid training, understanding the emergency protocols, and knowing how and when to use emergency equipment.

But safety training at Saws UK University goes beyond just the individual operator. It also addresses the broader workplace environment. This includes topics like maintaining a clean and organised workspace, proper storage and handling of materials, and understanding safety signage.

Our Safety Training program has a lasting impact on operations. It cultivates a safety-conscious culture where operators not only know how to operate the bandsaw safely, but also understand why these measures are important. Ultimately, the goal of our safety training is not just to reduce accidents, but to eliminate them. The program equips operators with the knowledge and awareness to do their jobs safely and effectively, ensuring a safe and productive working environment for everyone.

Saws UK University Training Program

At Saws UK University, we pride ourselves on delivering a comprehensive, top-tier bandsaw training program that marries theory with practice, creating a holistic learning experience. Our program caters to a range of skill levels, from beginners who are just starting their journey in bandsaw operations to seasoned operators aiming to sharpen their skills and stay updated with the latest developments.

Our training program encompasses a broad range of topics, reflecting the complex nature of bandsaw operations. The curriculum starts with the basics, such as understanding the machine parts, setting up the machine, and learning about various types of blades and their applications.

As participants progress, they delve into more advanced topics, such as fine-tuning machine settings for different materials, troubleshooting common issues, and mastering advanced cutting techniques.

The Saws UK management team are seasoned professionals with extensive experience in bandsaw operations. Their expertise provides invaluable insights into the practical aspects of bandsaw operation, helping trainees understand not just the how, but also the why behind different procedures and techniques.

Our goal is ultimately to provide world-class sawing machine, blade, and coolant education to our customers and distribution partners, which is why Saws UK University was created to provide the educational and operational sawing solution experience to plant saw operators, maintenance personnel, and department supervisors.

Share this post: