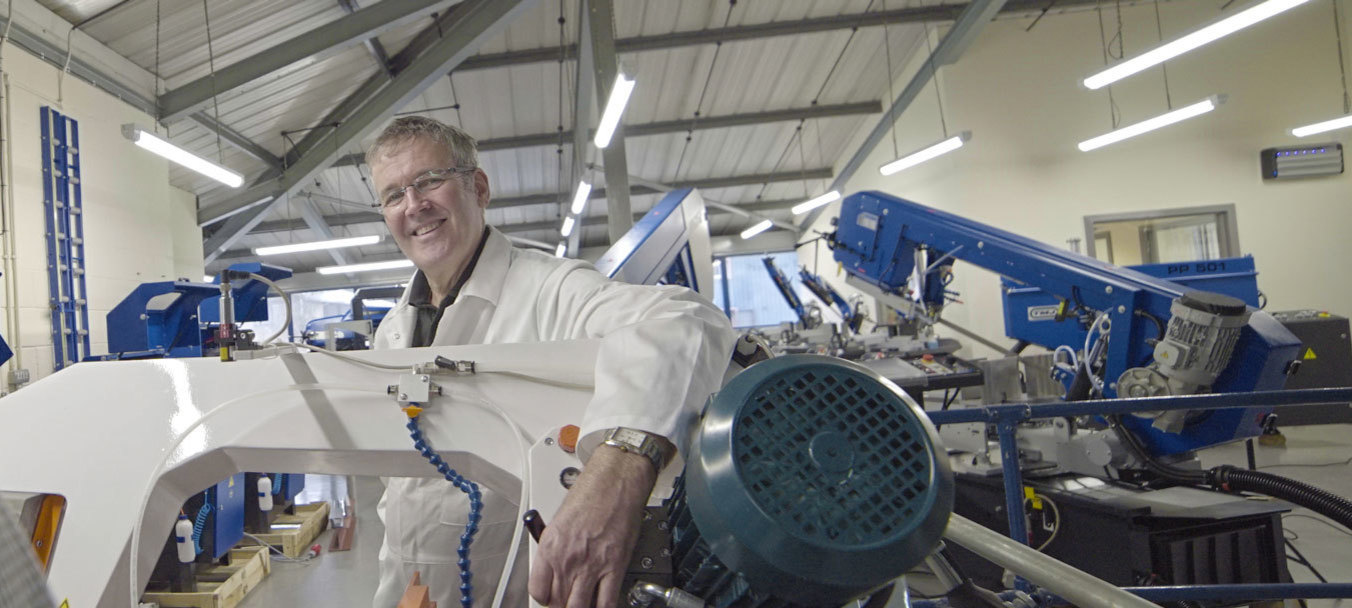

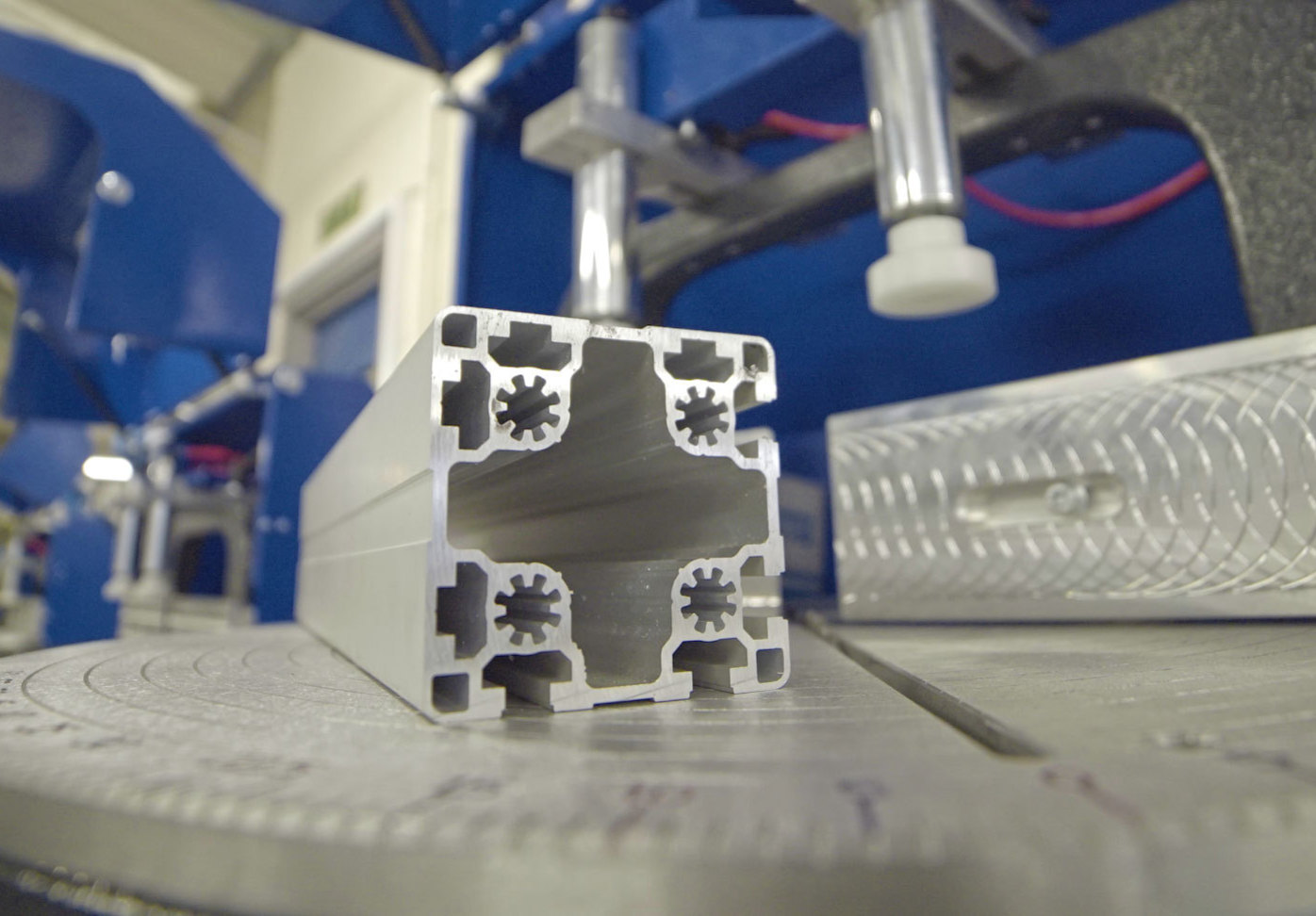

SAWS UK have been trading since 1989 offering bandsaws, bandsaw machines, metal cutting bandsaws and bandsaw blades to all sectors of industry. Our trade mark Alligator Bandsaws, Comet Circular Saws and Alligator Bandsaw Blades have been leading saw brands for many years. We offer all types of industrial bandsaws and metal cutting manual, semi-automatic, automatic, cnc band saws to suit many different applications. We are a UK agent for Doall, Carif, Meber, Macc, Bonetti, Rusch, Simec, Uzay Makina, Forestor Sawmills and Startrite bandsaws. We have a new range of Education Sector Bandsaws. Want a demonstration of a particular machine at our showroom? Need help choosing a newer / replacement machine? Want to find the right roller table to use with your particular metal cutting machine, bandsaw or circular saw? Do you need advice on measuring systems? Our expert team can help! Do not hesitate to contact us.

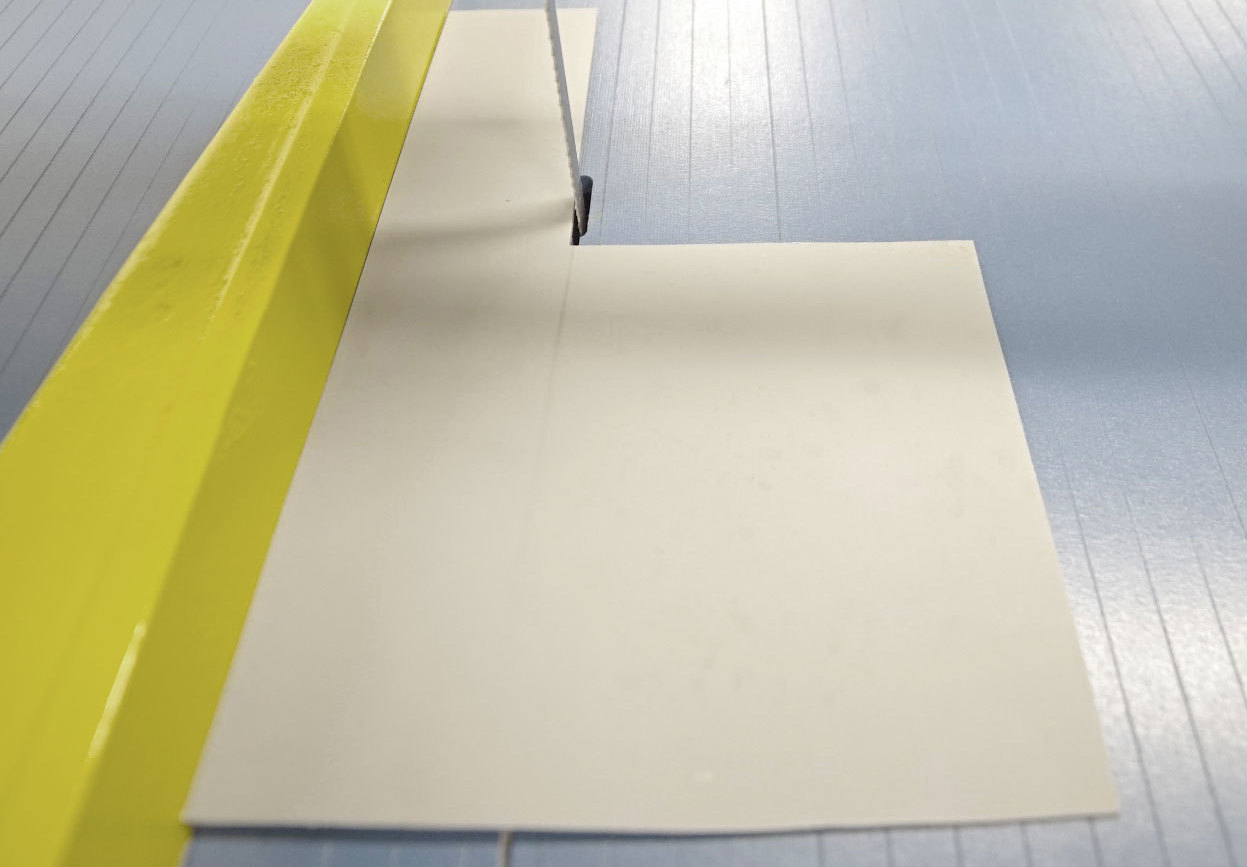

WHAT DO YOU CUT? We have the machine for you. Click the links below to find the machines that cut your material.

SAWS UK: Providing you with the right saw for the right purpose. We commission and we service. All backed up with a warranty*