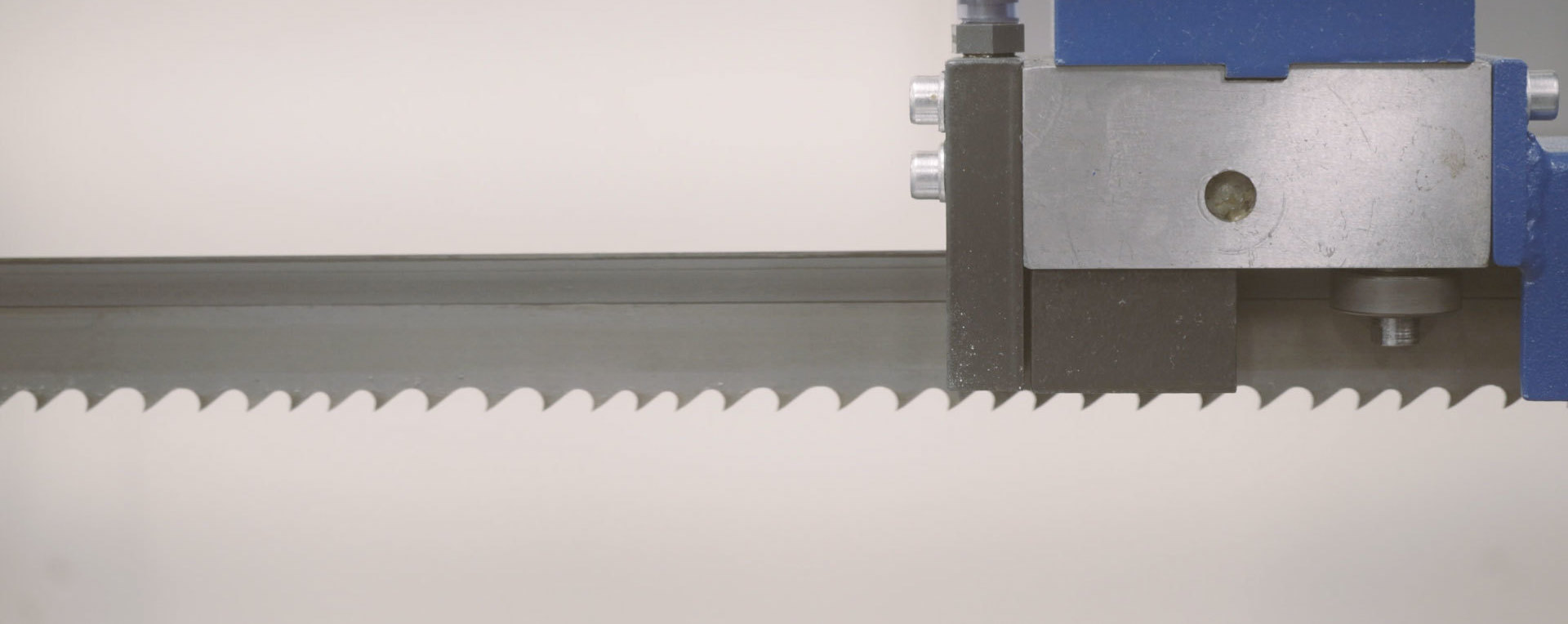

SELECTING THE RIGHT BLADE PITCH FOR YOUR BANDSAW

To get the right cut and to avoid wasting materials or blades, it's vital you select the right blade pitch. At Saws UK, we estimate that nearly 50% of bandsaw machines are using the wrong tooth pitch for the section of work being cut. This can cause costly mistakes.

As a rule, at least three teeth should be engaged in the material, with a maximum of 18. At one extreme, you could have teeth straddling the material causing excessive shock and the tooth to snap off. At the other extreme, too many teeth will cause the tooth gullets to be overfilled. This could cause overload to the teeth and result in excessive heat, which will eventually strip all the teeth off.

Tips of hard teeth could even be left in the material meaning you won’t be able to re-enter the cut with a new blade as it would also be destroyed by cutting through teeth debris. The only solution in this scenario is to shift the material along a little and do a fresh cut.

Sometimes, it’s difficult to use the correct blade pitch because of the complexity of the cut and so compromise is necessary. For example, a very large box section will consist of two large flat sections (effectively solids) and two thin sections being presented to the blade. Alternatively you may be cutting a wide variety of shapes, solids and profiles and you don't want to spend most of the day changing blades! But even in these scenarios, there are blades that will be much more suitable to complete multiple tasks.

If you’re not sure of the right blade, our expert team can give you a chart to ensure you choose the right one for your bandsaw machine. Just call us on 01892 663398 or email [email protected] for guidance.

Alternatively, you can buy bandsaw blades online or order custom blades from our helpful team.

Tagged as: Bandsaw Blades, Bandsaw Machines

Share this post: