Extending Your Bandsaw Blade Life (Cutting with Lubrication)

Prolonging the life of your valued bandsaw blade is made much simpler by using the correct lubricant. In fact, this is essential. Failing to do so when cutting metals will mean damage to the teeth of the blade and too much friction created, potentially damaging the material as well.

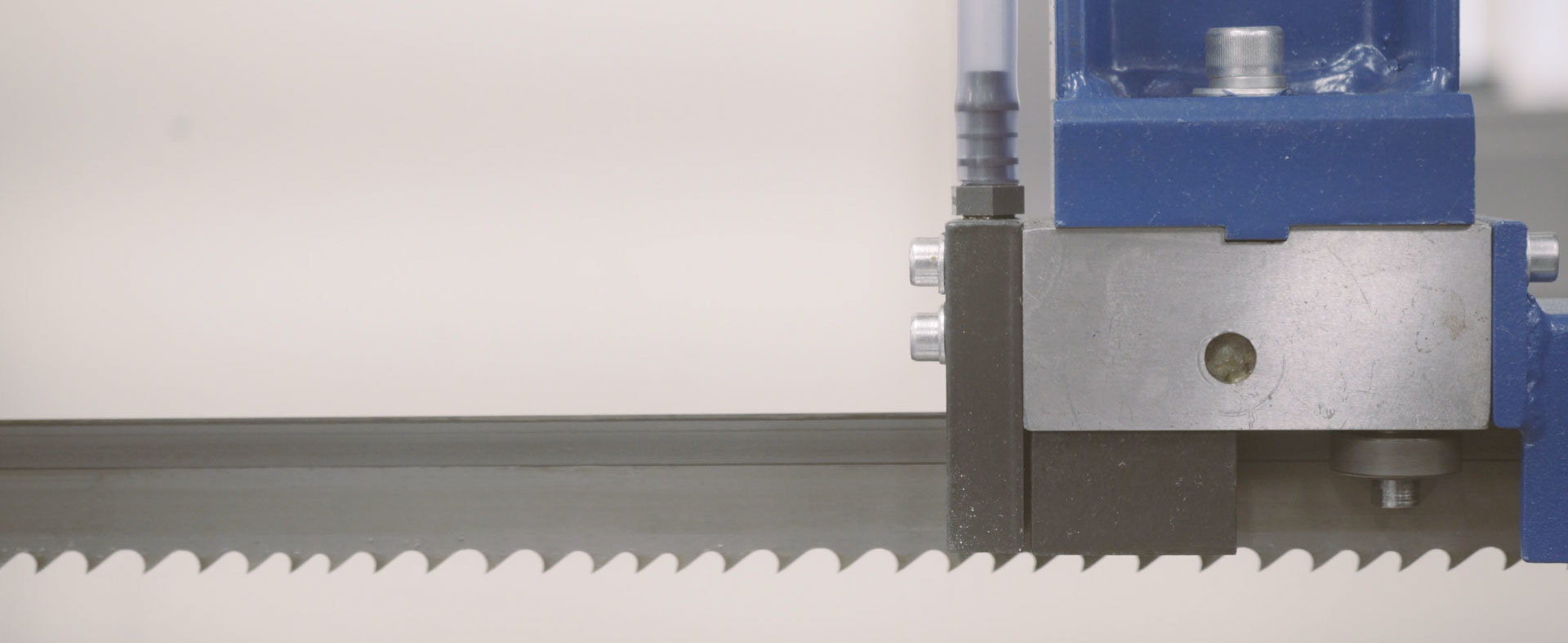

Chips stick to blade gullets without lubrication

The act of sawing results in a lot of heat. This is because chips are sheared from the material due to the friction involved in the metal-to-metal contact at high speeds. So, when the blade overheats its teeth will wear down faster because those chips will weld into the gullets of the blade. Using a lubricant can stop the chips welding to the tooth, meaning the bad gullets will stay cleaner and, quite simply, work well for longer. A further bonus is that your cuts will be far neater.

Lubrication works by ‘coating the blade’ to prevent damage

How the lubricant works is that it cools down the blade, lubricates the teeth and gets rid of any chips that just happen to be there. Lubrication used for bandsaw cutting tends to be quite a rich formula to cope with the high speeds used in such cutting. The lubricant needs to be able to coat the blade well.

While cutting, it’s important to make sure that the lubricant is indeed doing its job i.e. that it’s washing over the blades when the bandsaw both enters and exits the cut. The lubricant is then recirculated. Watch too for any loose chips blocking the flow of the lubricant by getting into the lubrication system. Leaks with the lubrication system too can be a problem if not checked regularly.

Not all lubricants are equal

As with most things in life, lubricants vary depending on what they contain and how much they cost. The type of lubricant you use also depends on what kind of cutting you plan on doing. Using the wrong lubricant will damage the blade and clog your machinery. Getting the correct lubrication though will result in a smooth cut as well as protecting and prolonging the life of your precious blade.

For more information- or if you’re not sure of the right lubricant, our expert team can give you a chart to ensure you choose the right one for your bandsaw machine. Just call us on 01892 663398 or email [email protected] for guidance.

Alternatively, you can buy a selection of lubricants and blades online or order custom blades from our helpful team.

Share this post: