Blade Terminology and Material Blade Types

When it comes to band sawing, it's not just the design of your blade or the material to be cut that's important. It's also necessary to have the correct blade in the first place.

In other words, to get the most economic cut possible when band sawing it's necessary to choose a blade with the correct number of teeth per inch (TPI). This number will vary depending on the material you intend on cutting. Soft materials, such as aluminium, will need a different amount of TPI on a high band speed, compared to harder metals, for instance.

The TPI depends too on whether you are cutting individual pieces of material or bundled amounts. If it's the latter then the guidance is to find the TPI for one piece and increase this by a pitch in order to tackle the bundle.

Please note: the positioning of material in a vice can also alter the TPI on a blade, as can the size and shape of the material.

There have been a number of new techniques introduced to the band sawing sector within recent years. So, to make sure you are armed with enough knowledge to benefit from them, here is our at-a-glance guide to blade technology:

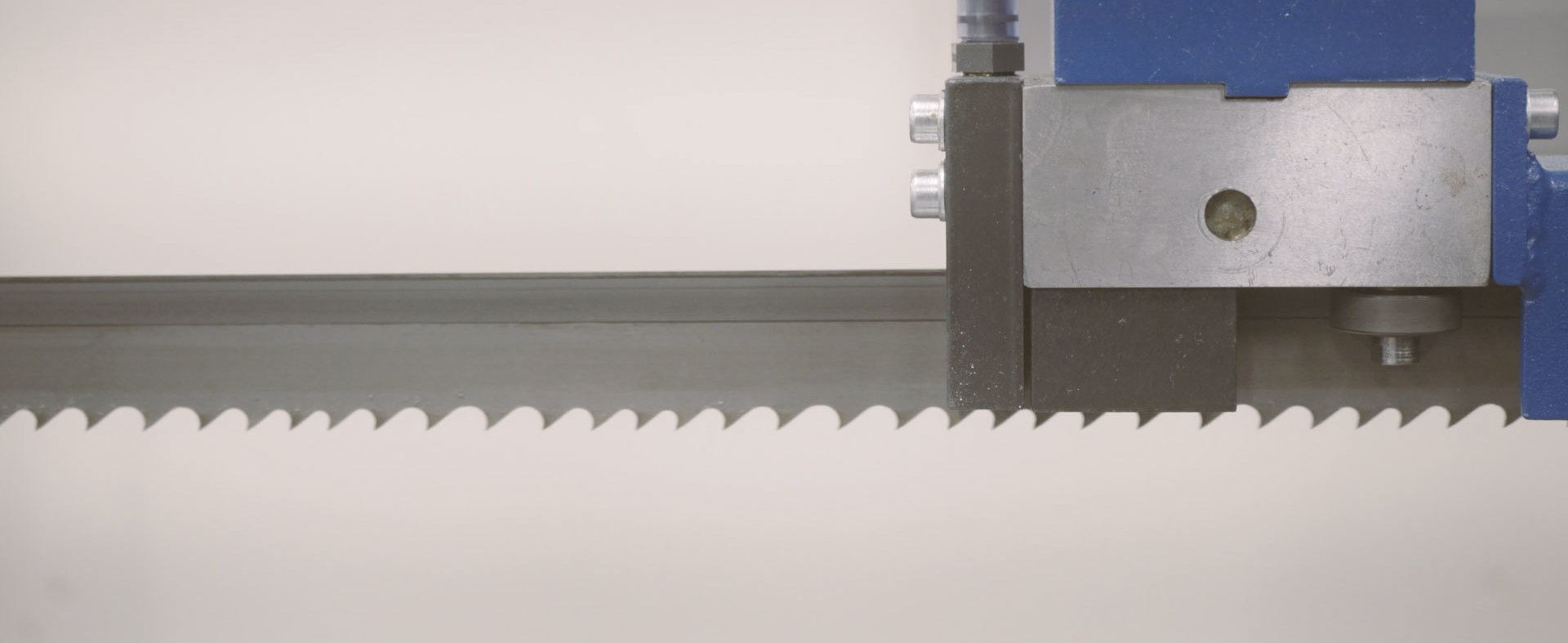

Tooth Face. This is the surface of the tooth.

Tooth Pitch. Also known as the distance between the tip of one tooth and that of the nearest tooth.

Gullet. This is the curved area you find at the bottom of the tooth.

TPI. This stands for teeth per inch and is the measurement between the gullets.

Tooth Rake Angle. The angle referred to is that of the tooth face perpendicular to the direction in which the saw is cutting.

Blade Width. This is the measurement you find between the end of a tooth and the back of the band.

Blade Thickness. This refers to how much the saw measures between either side of the blade.

Blade Set. When you bend the teeth right or left there is a certain amount of clearance from the back of the blade through the cut. This is known as the 'set.'

Blade Back. As the name suggests, this is the opposite side of the blade to the teeth.

Kerf. This is the material that is discarded when the blade cuts through the item.

For more information- or if you’re not sure of the right blade, our expert team can give you a chart to ensure you choose the right one for your bandsaw machine. Just call us on 01892 663398 or email [email protected] for guidance.

Alternatively, you can see more about our range of our UK-made bandsaw blades or buy bandsaw blades online in our new shop.

Tagged as: Bandsaw Blades, Bandsaw Tooth Pitch

Share this post: