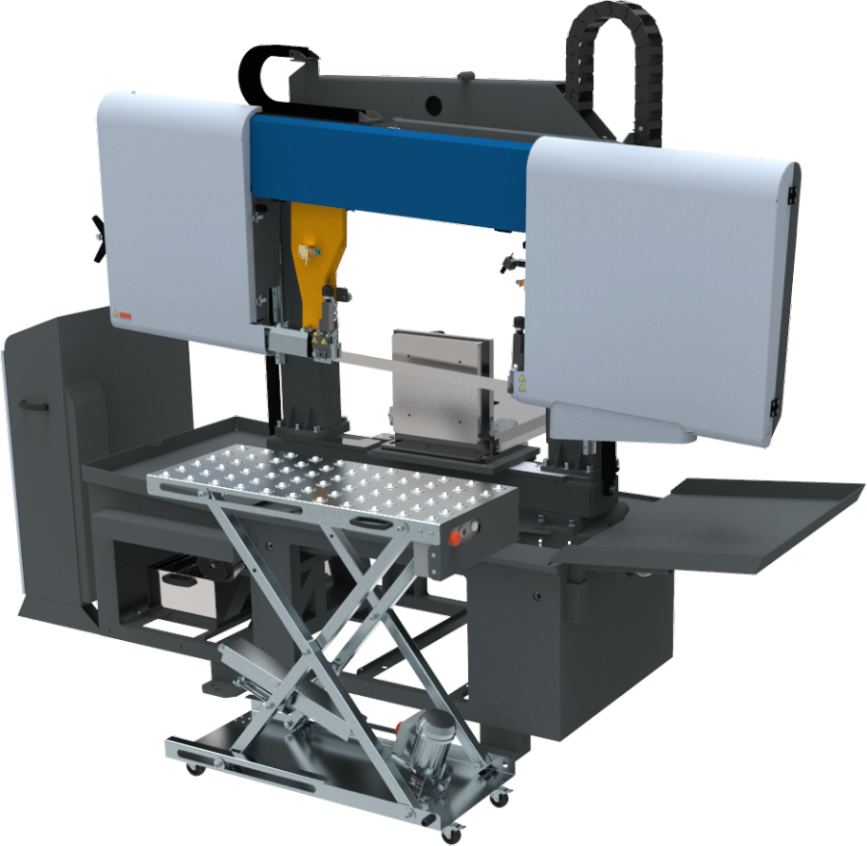

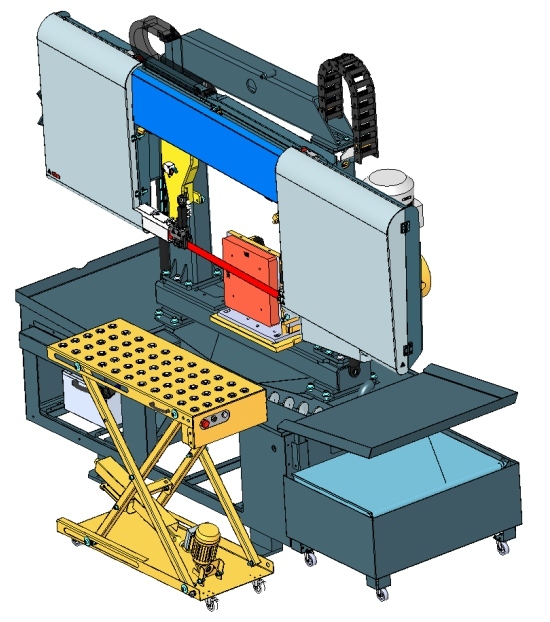

ALLIGATOR XPERT 5.2 3D BANDSAW

3D Cutting Bandsaw

This robust two-column band saw ensures a fast and precise division of the 3D printer product from the printing plate. The cutting accuracy is 0.2 mm in all directions, the cutting width is approximately 2 mm.

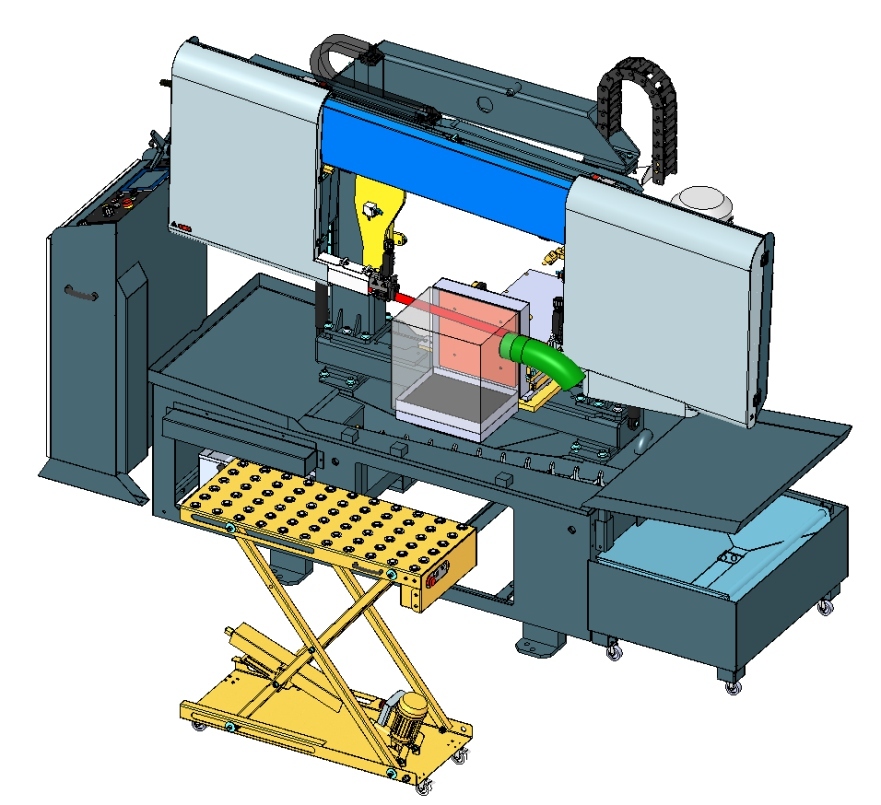

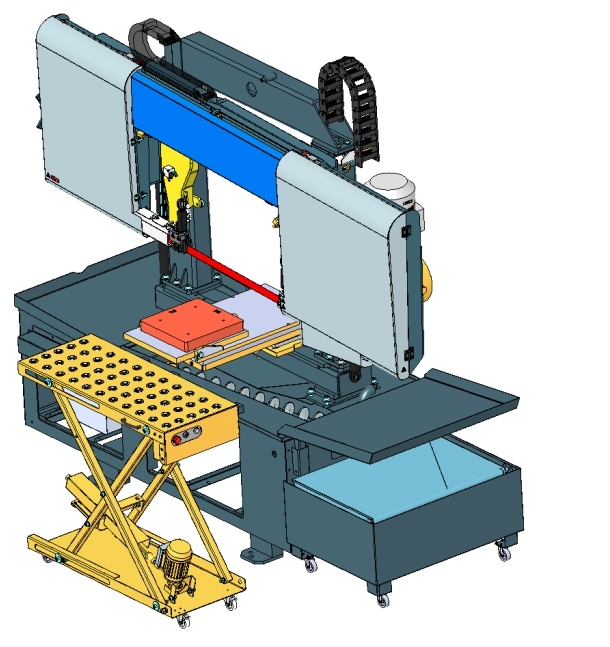

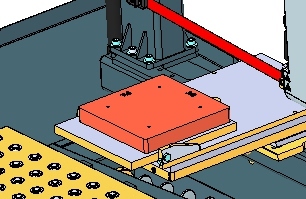

A special adjustable printing plate clamping system ensures optimal fixation. It is equipped with a tipping mechanism with stops. This allows easy and fast clamping of the printing plate in the horizontal position and simple tipping to the vertical working position. Precise clamping of the printing plate ensures a cut setting with minimum allowances, which saves material when printing. The distance between the cut and the base plate is set automatically. The printing plate moves on the linear guiding using a hydraulic cylinder driven by a powerful hydraulic unit. Folding of the printing plate is done by hydraulic power as well. The complete cutting process with printing plate folding is made automatically.

The maximum printing plate size is 500 x 500 mm.

The continuously adjustable jaw of the clamping system allows the installation of a 10–60mm thick printing plate with the possibility of adjustment up to a range of 0–500 mm.

The machine is seated on an innovative base, which was designed with an emphasis not only on sufficient stability but also on minimum size (the base width is only 980 mm).

The machine is characterized by its overall robust design. Its base consists of a stable machine pedestal with the printing plate clamping system and a two-column fitting system of the arm that moves on linear guiding. The saw blade arm moves on the linear guiding using a hydraulic cylinder driven by a powerful hydraulic unit. The unique saw blade arm is fitted with orbital cast-iron wheels with a massive fit, driven by an industrial motor with a worm gear. All this guarantees long-term cutting precision and the service life of the machine. The machine features simple operation on a central control panel and an infinitely adjustable feed rate into the cut. After the execution of the cut, the saw blade automatically turns off and its arm moves up to the original, adjustable position.

The cutting tool used is an industrial Bi-metal saw blade of the size 34 x 1.1 mm. The precision of the cut is guaranteed by a three-sided hard metal guiding before and after the cut. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band speed by a frequency converter in the range between 20-130 m/min., which significantly contributes to cutting accuracy and service life of the saw bands.

The lighting of cutting is solved by an LED lamp.

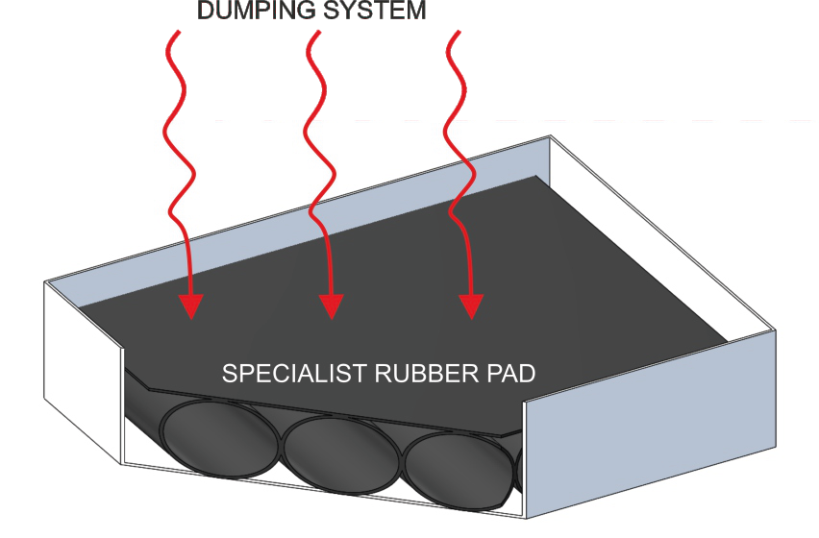

We offer a transparent box where the parts can fall down on the rubber pad. lt is a system that prevents dispersion and collects metallic particles. The vacuum cleaner is not part of the offer. This solution is designed for dry cutting.

We can also adapt and customise the machine to whatever you are trying to achieve with it.

All Enquiries

Saws UK: Providing you with the right saw for the right purpose. We commission and we service. All backed up with a 10 Year warranty*